Contact No.

Scan the QR to call

| CALL NOW | : | +91-9879615961 |

|---|---|---|

| : | (+91-9879615961) | |

| Availability | : | In Stock |

| Eligible Region | : | India |

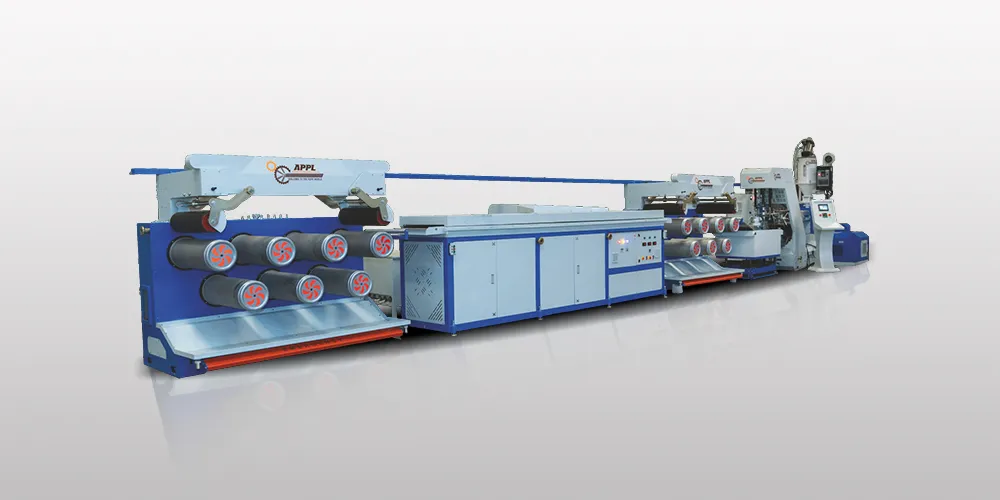

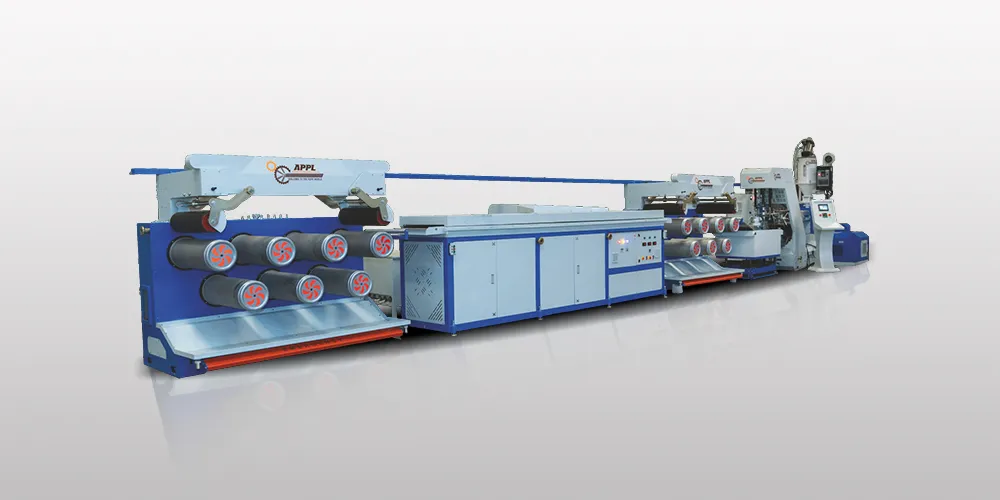

| Brand | : | Aawadkrupa Plastomech Pvt. Ltd. |

| Category | : | Extrusion Plant |

| Model Name | : | 2-6 mm to 25-55 mm |

| Payment Methods | : | Cash, UPI, Net Banking |

| Google Rating (4.4) | : |

Extrusion plants are industrial facilities that specialize in the process of extrusion. Extrusion is a manufacturing process that involves pushing or forcing a material through a shaped die to create a continuous profile with a fixed cross-sectional shape. This process is commonly used in the production of plastic, metal, and food products.