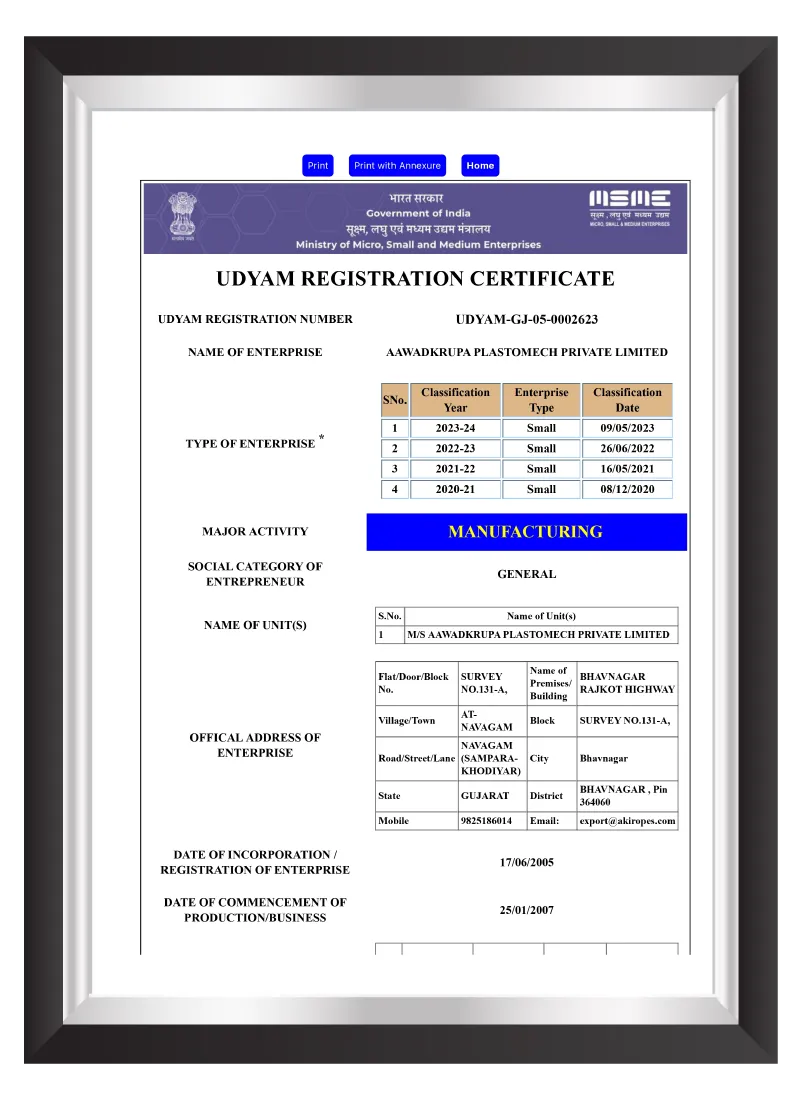

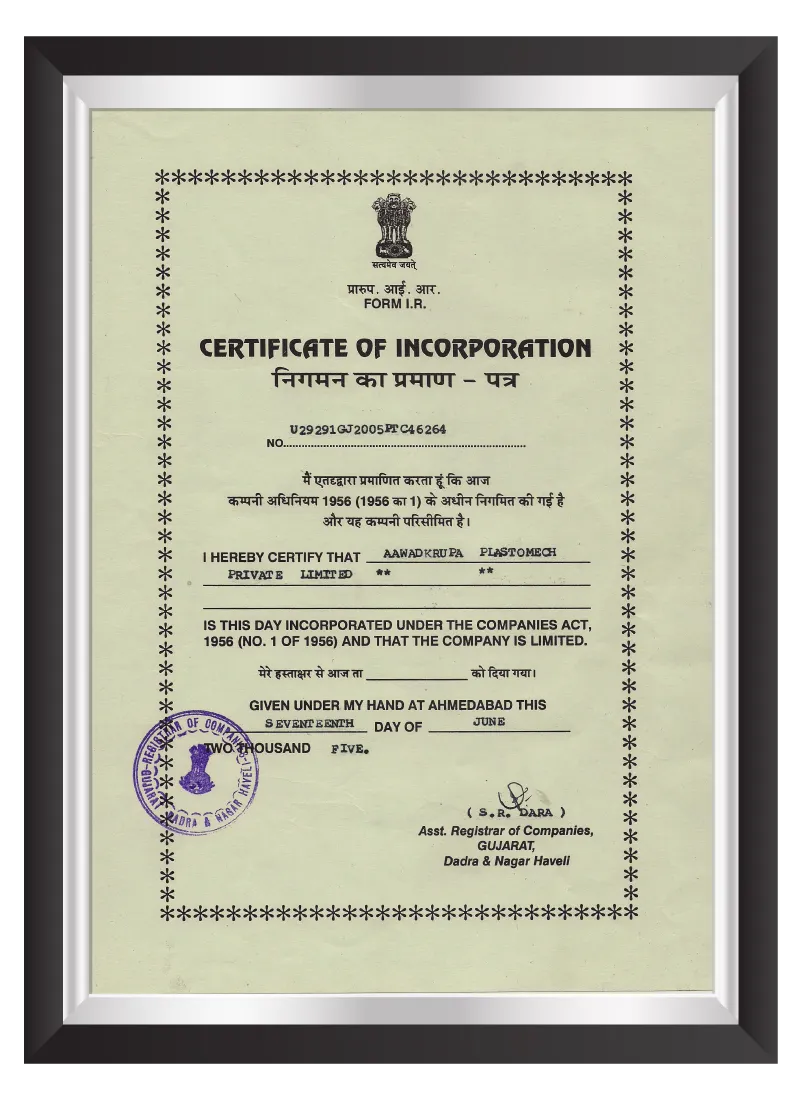

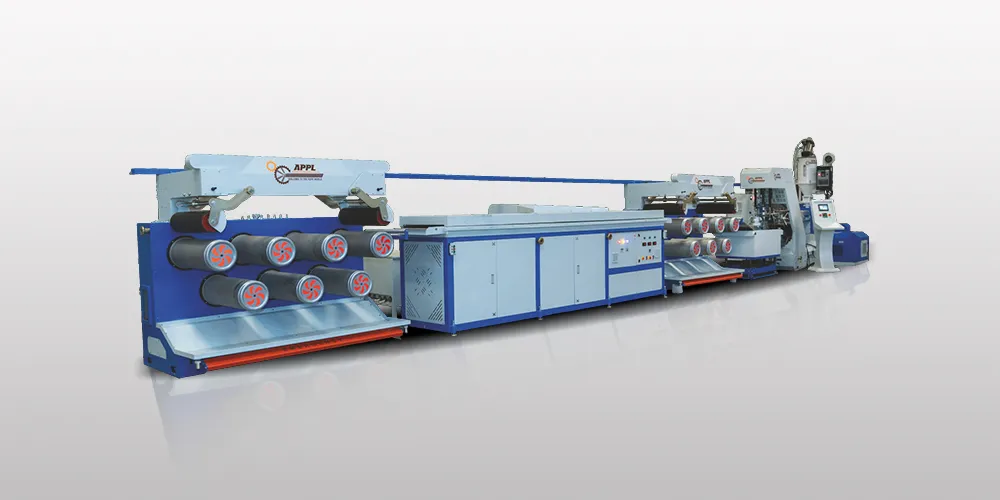

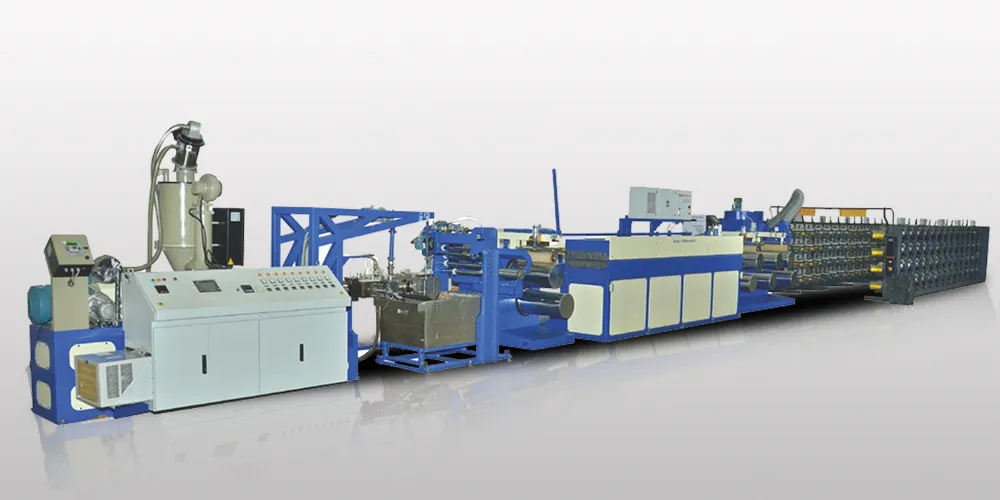

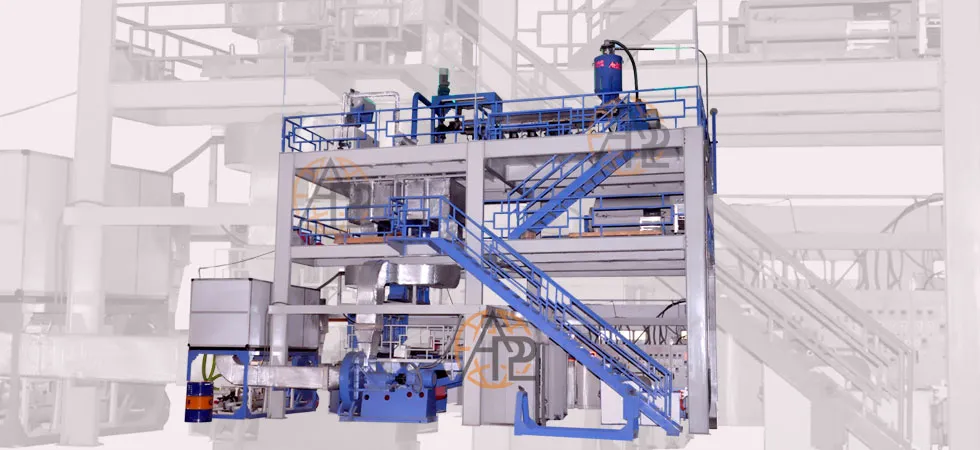

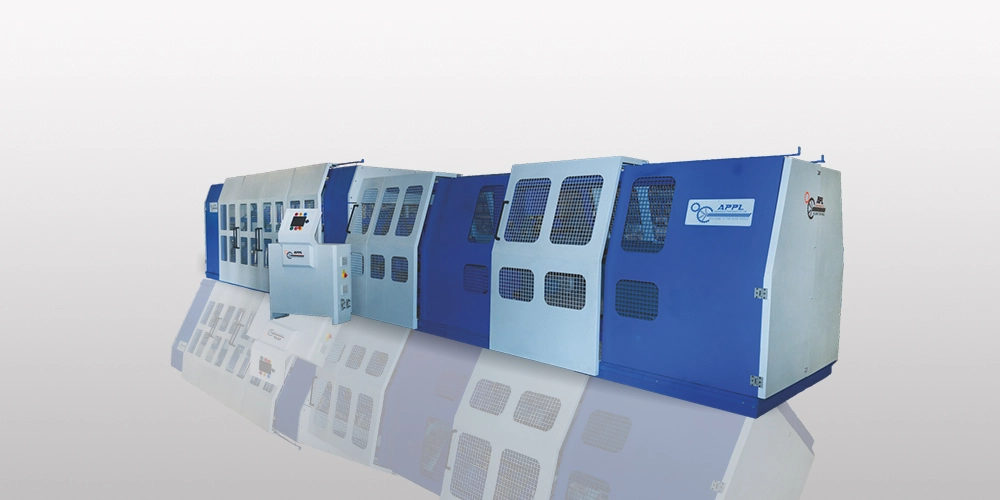

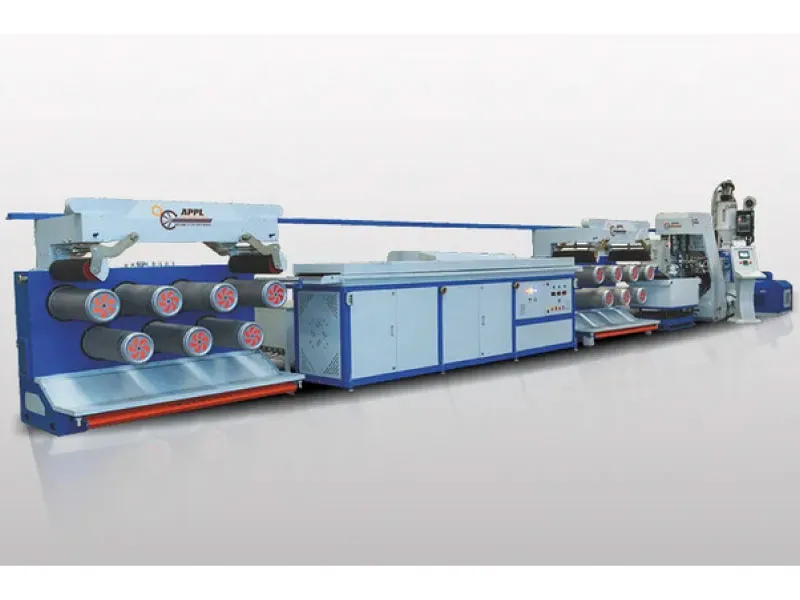

Aawadkrupa Plastomech Pvt. Ltd. is a leading manufacturer and exporter of high-quality PET Strap Extrusion Plants. Our company is known for providing top-of-the-line machinery that produces strong and reliable PET straps for securing and bundling goods during transportation. With a global customer base, we ensure that our machines deliver the best performance and meet the highest quality standards.

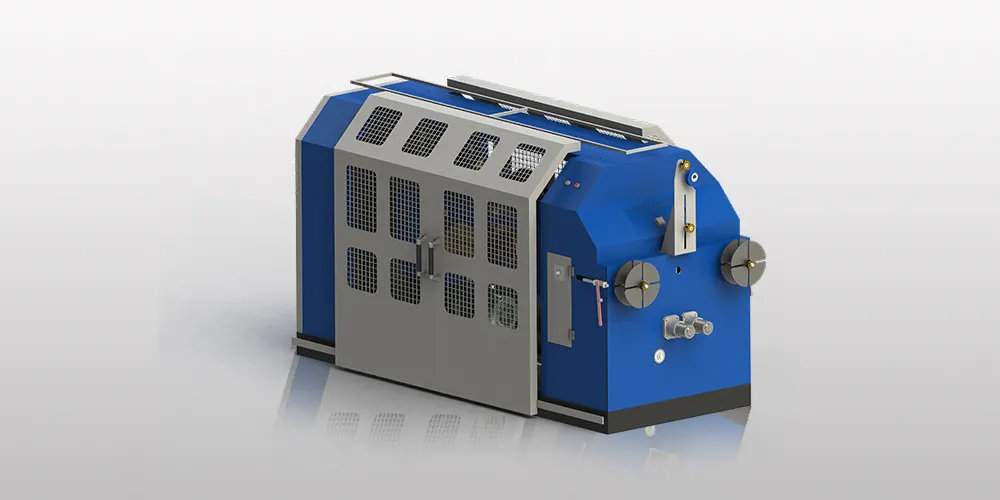

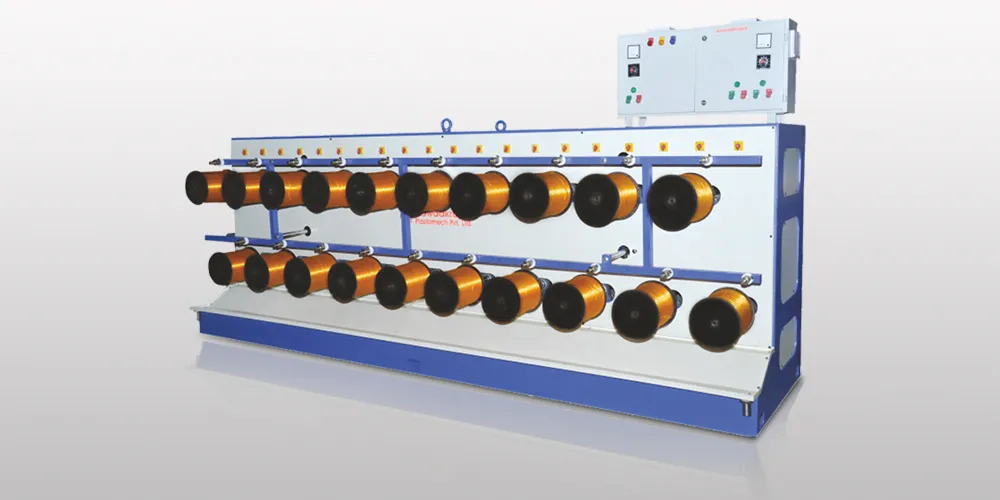

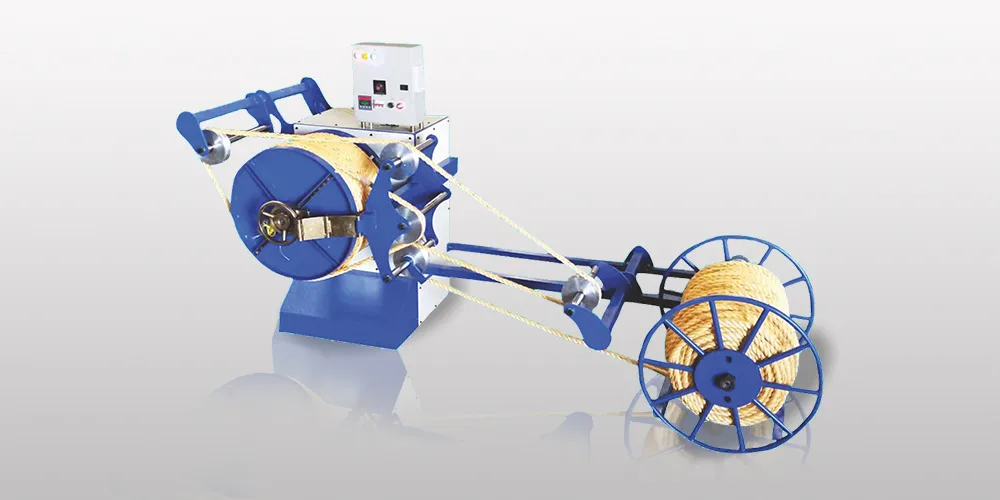

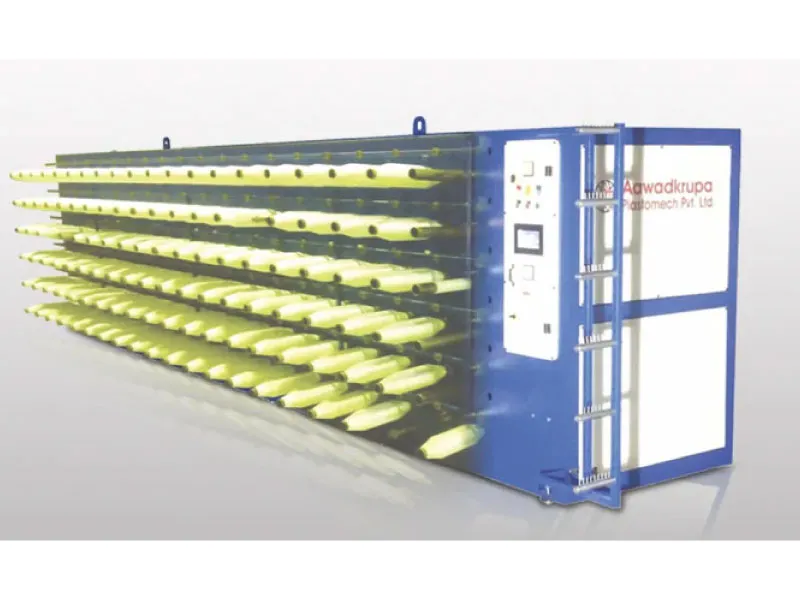

Our PET Strap Extrusion Plant converts polyethylene terephthalate (PET) resin into durable straps of various widths and thicknesses. The process starts with melting the PET resin, followed by mixing in additives to improve the material’s durability and color. Once mixed, the material is shaped through a die, cooled, and solidified. Finally, the finished product is rolled onto spools for easy handling and storage. This efficient process results in strong PET straps that are ideal for securing goods in industries such as packaging, logistics, and shipping. Aawadkrupa Plastomech ensures high quality and reliability with every machine we produce.