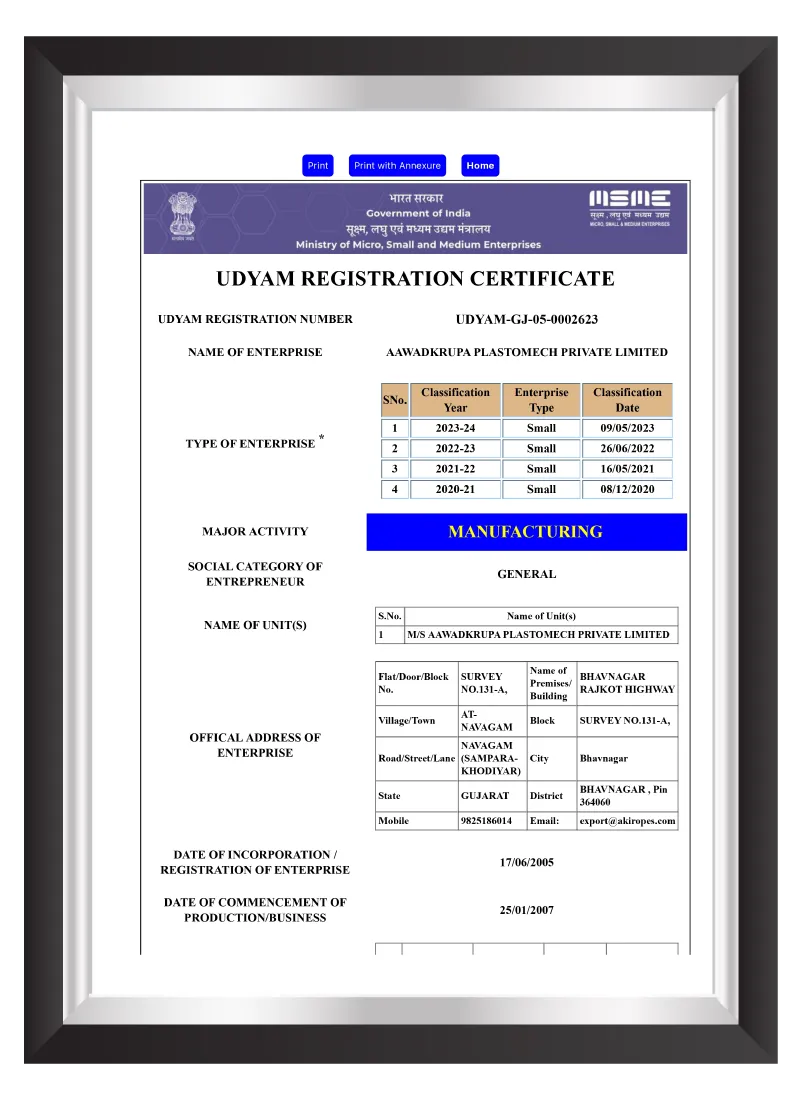

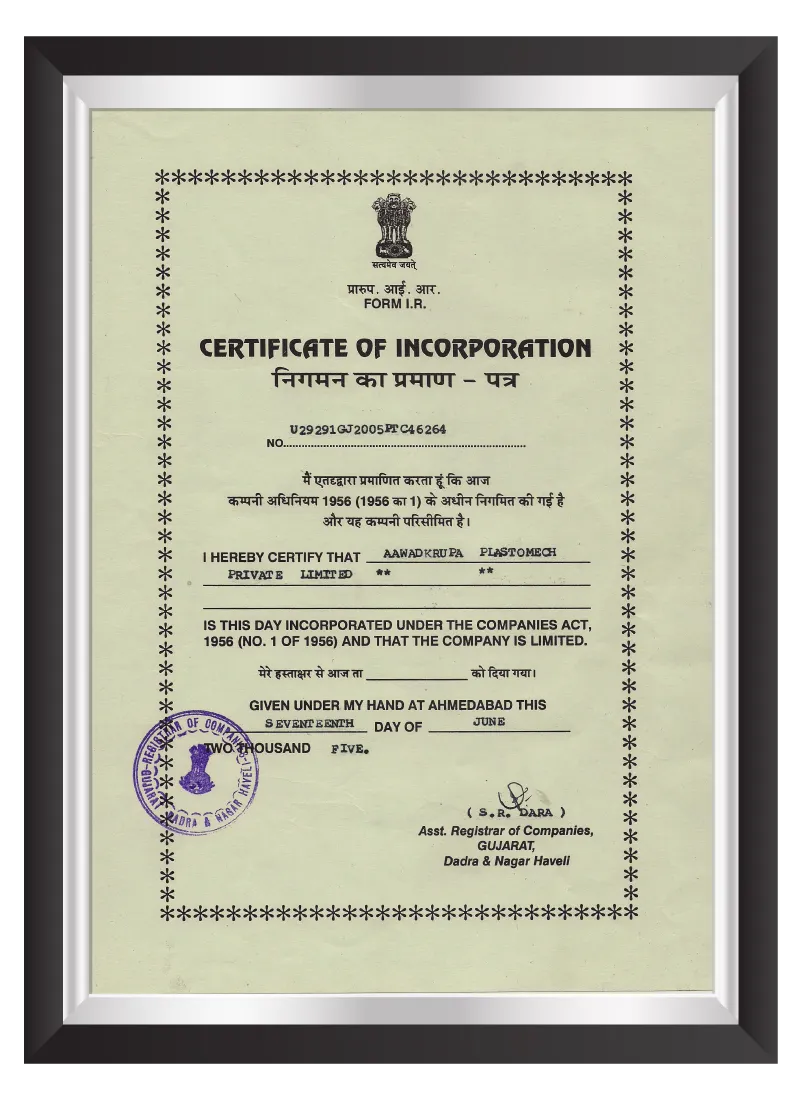

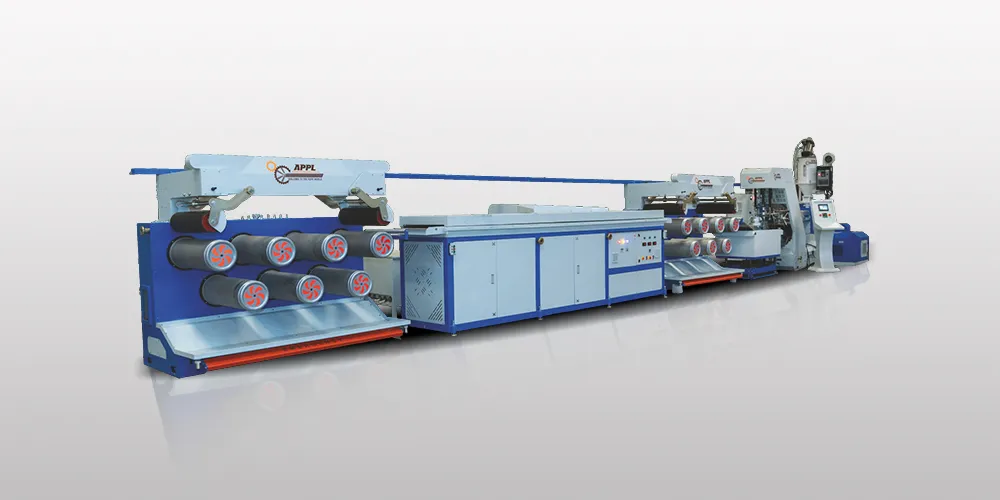

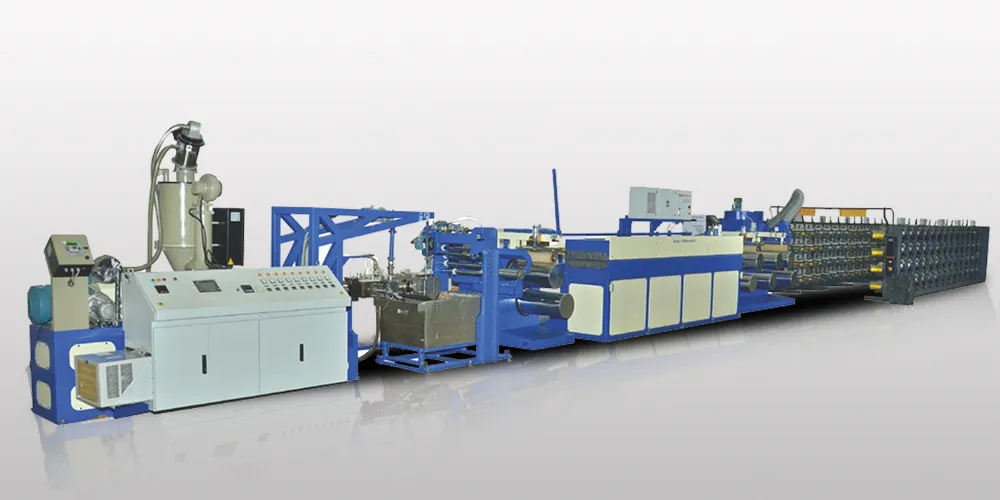

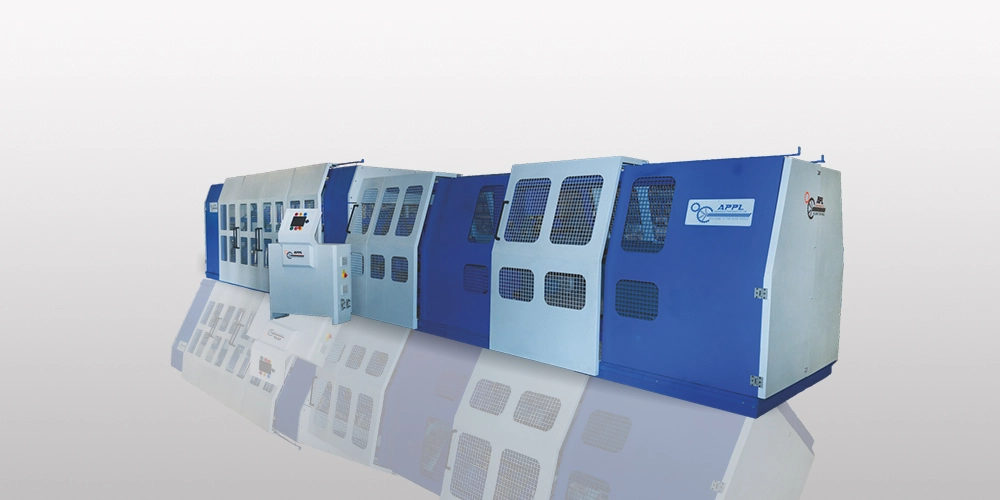

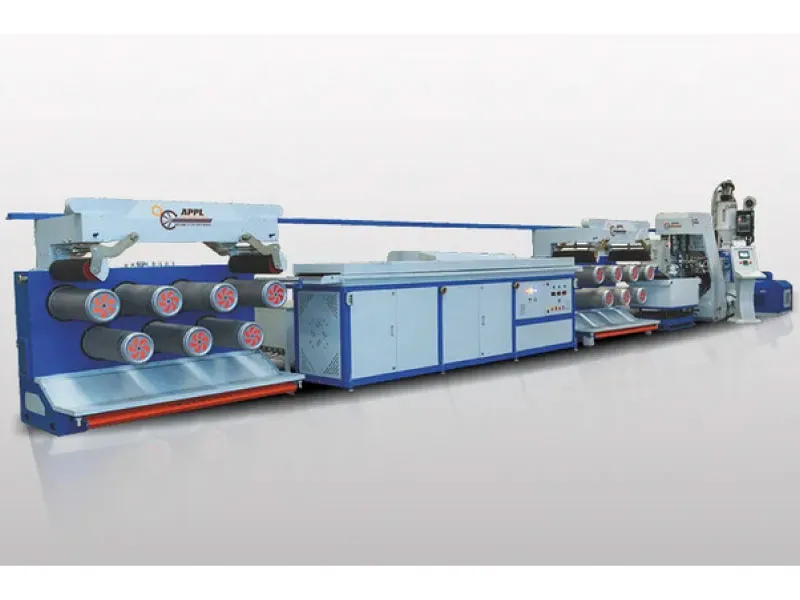

Aawadkrupa Plastomech Pvt. Ltd. is one of the leading manufacturers and exporters of high-quality PET monofilament extrusion plants. With decades of industry experience and a commitment to innovation, we deliver advanced and reliable machinery designed to meet the increasing global demand for PET monofilament production.

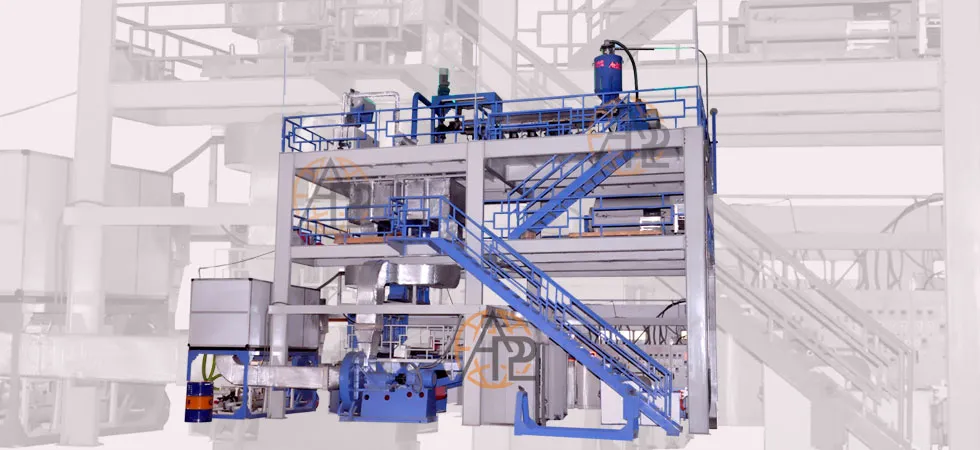

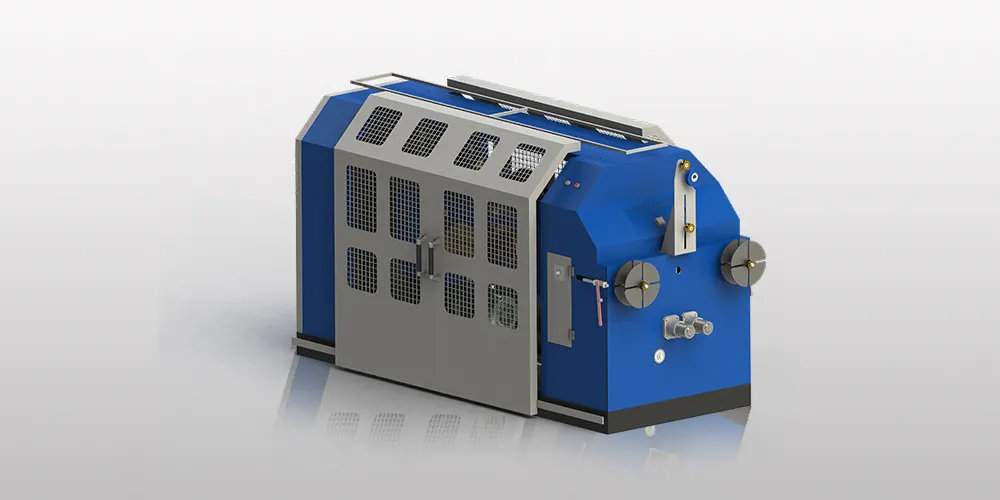

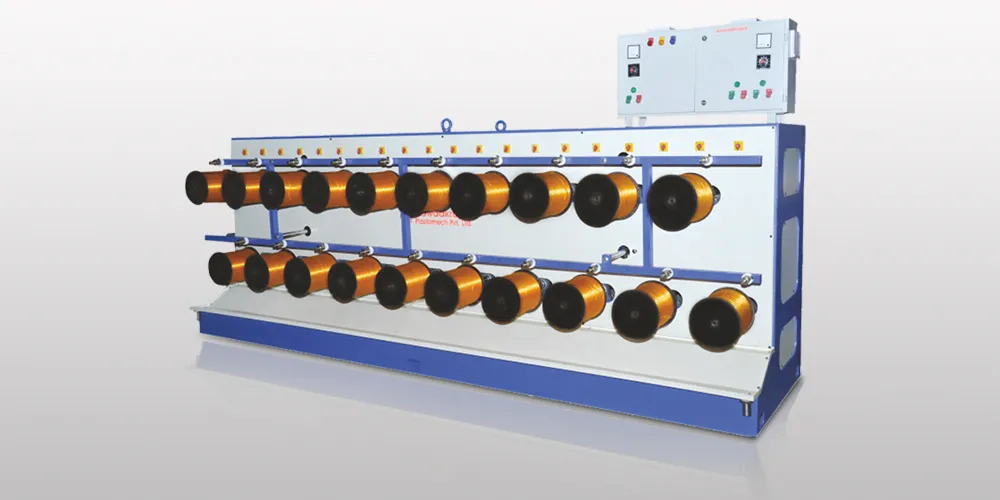

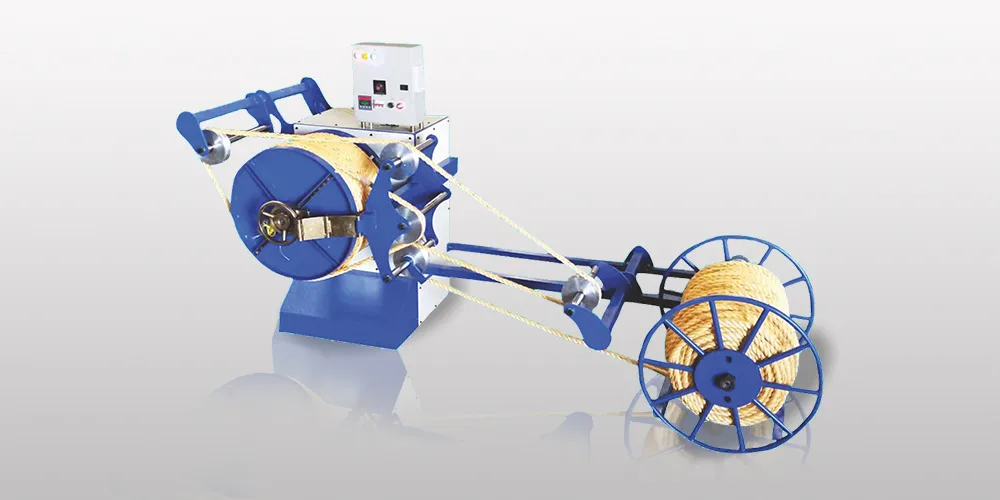

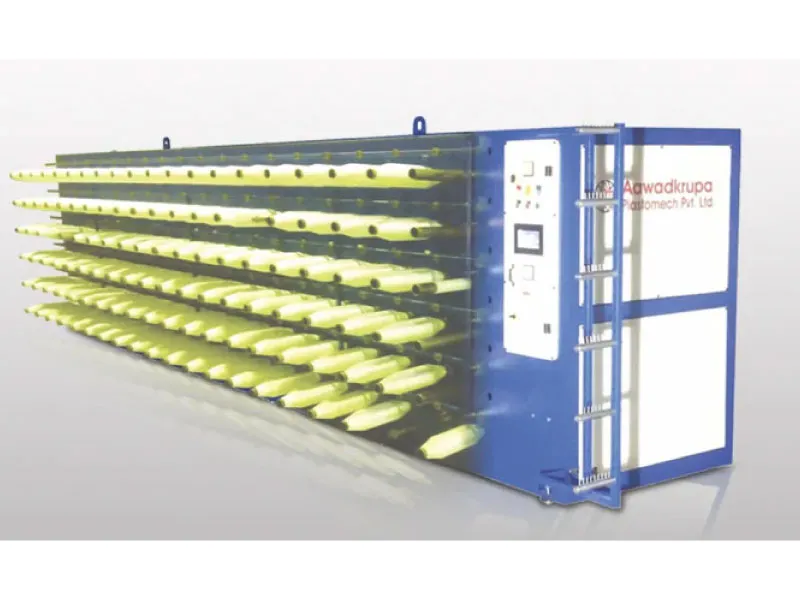

Our extrusion plants are engineered with precision and built using the latest technology to ensure smooth operation, energy efficiency, and long-lasting performance. These machines are ideal for producing consistent, high-strength PET monofilament used in various industrial applications.

As trusted manufacturers and exporters, we offer complete support—from customized machinery design to installation, training, and after-sales service. Whether you’re upgrading your current system or starting a new project, our solutions are tailored to enhance your production capabilities.

At Aawadkrupa Plastomech, we focus on quality, customer satisfaction, and long-term partnerships. Choose us as your PET monofilament extrusion plant partner and experience the growth, efficiency, and success our technology brings to your business.