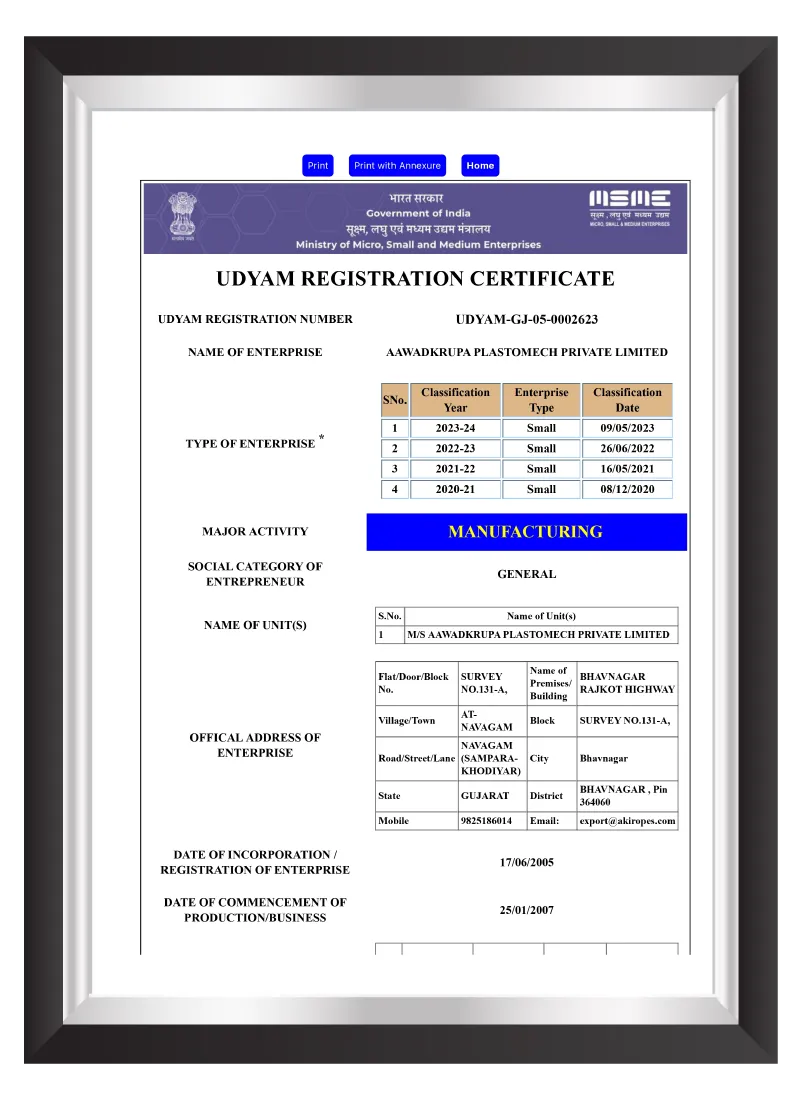

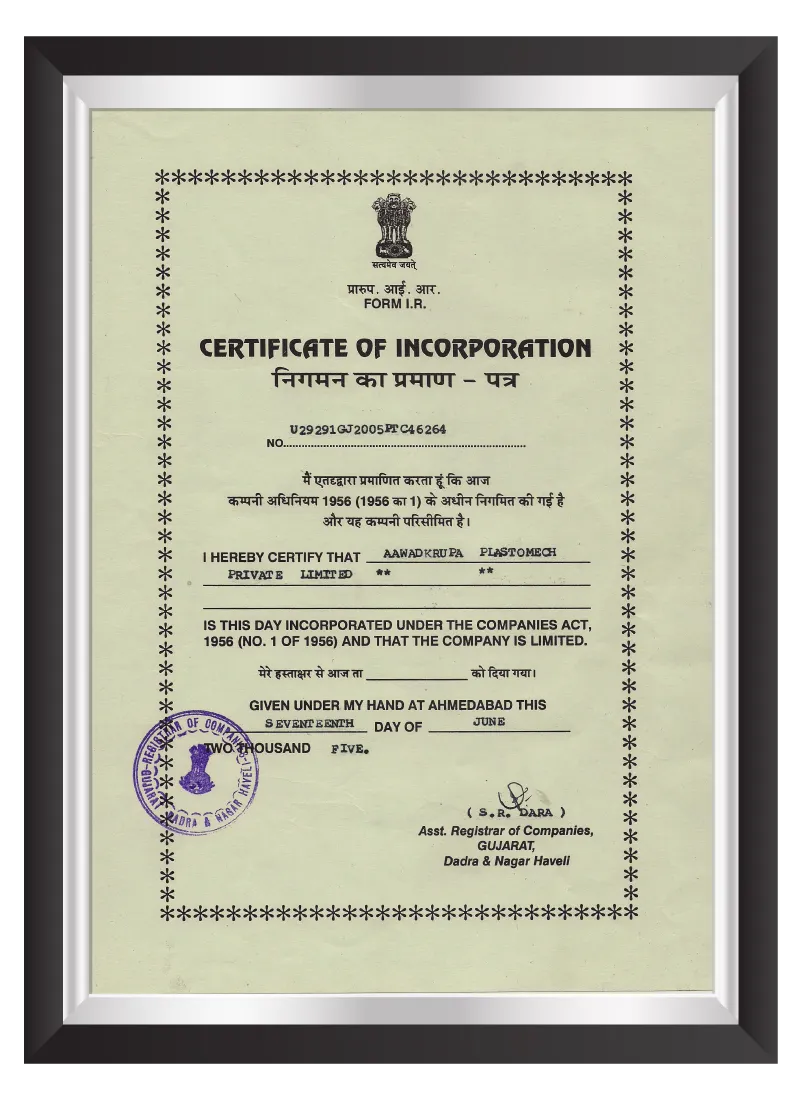

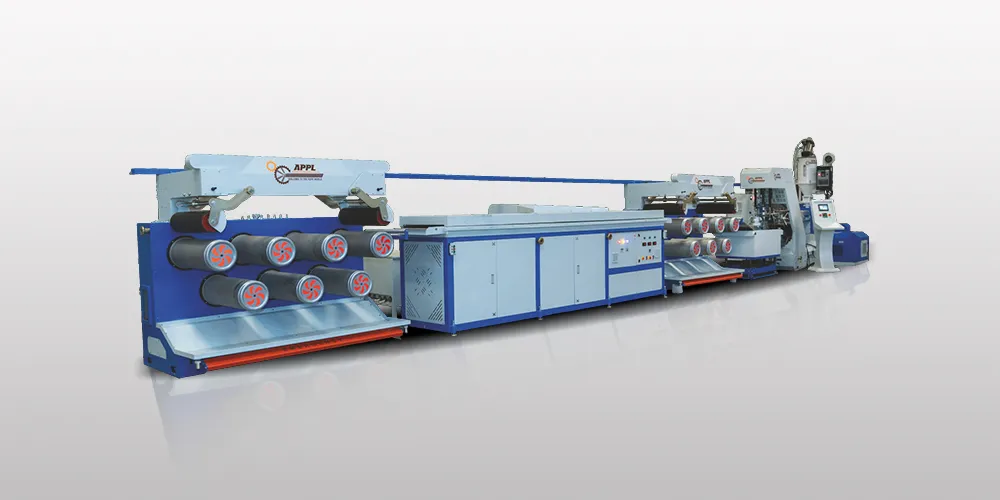

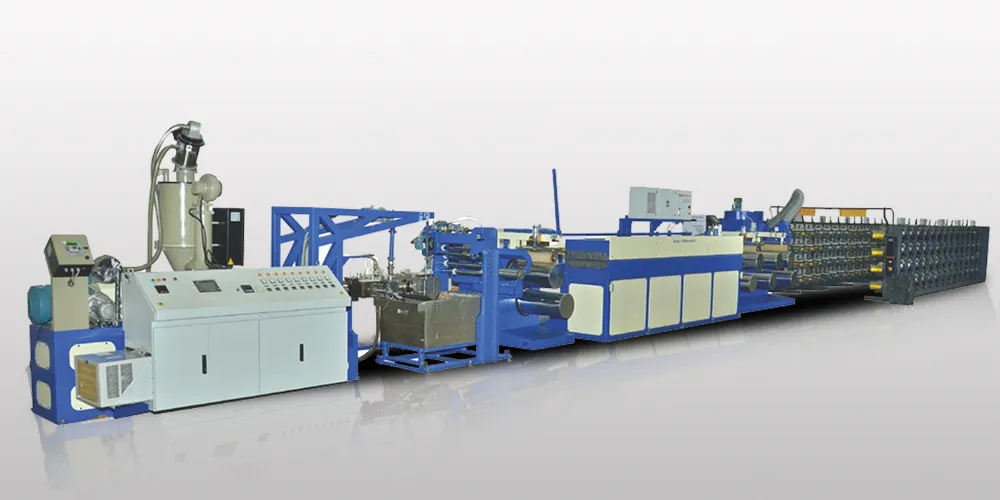

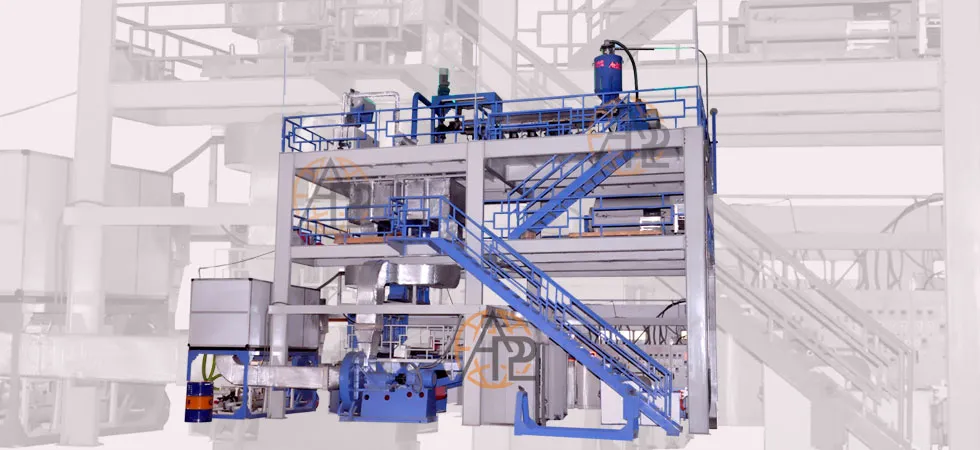

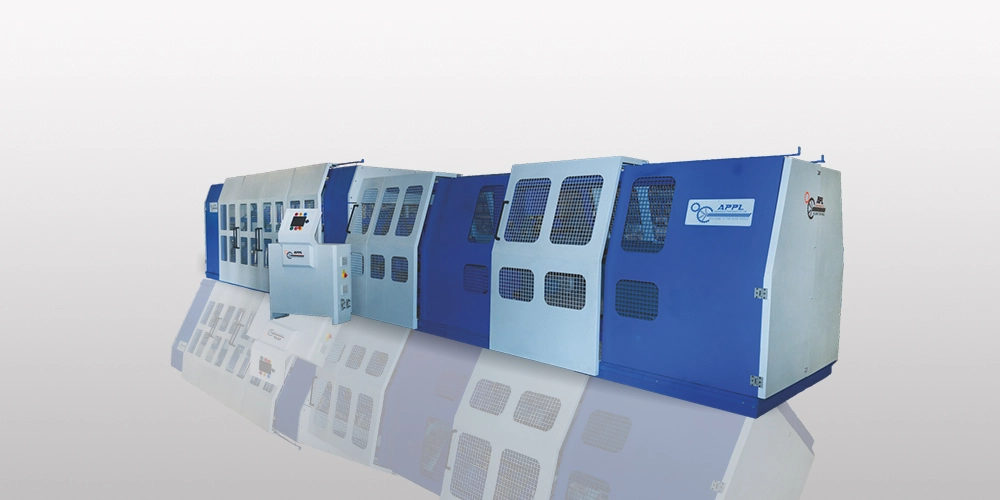

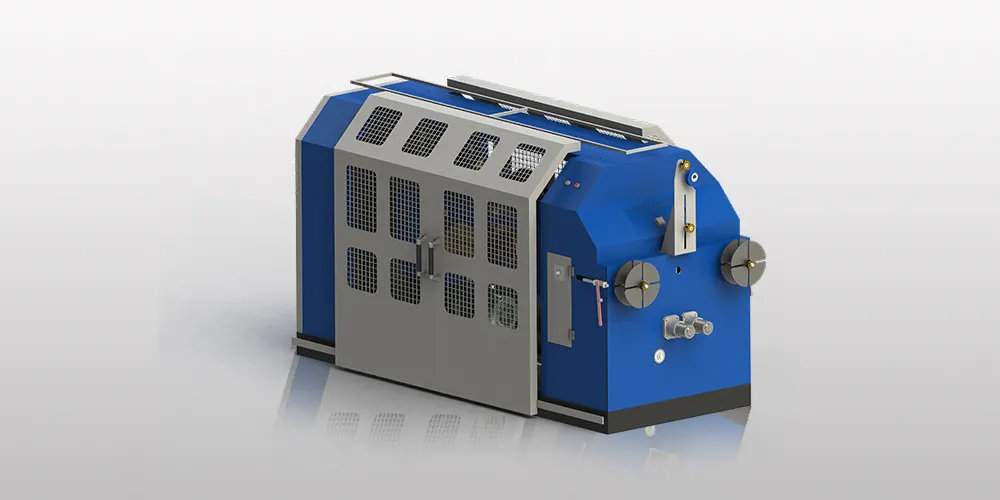

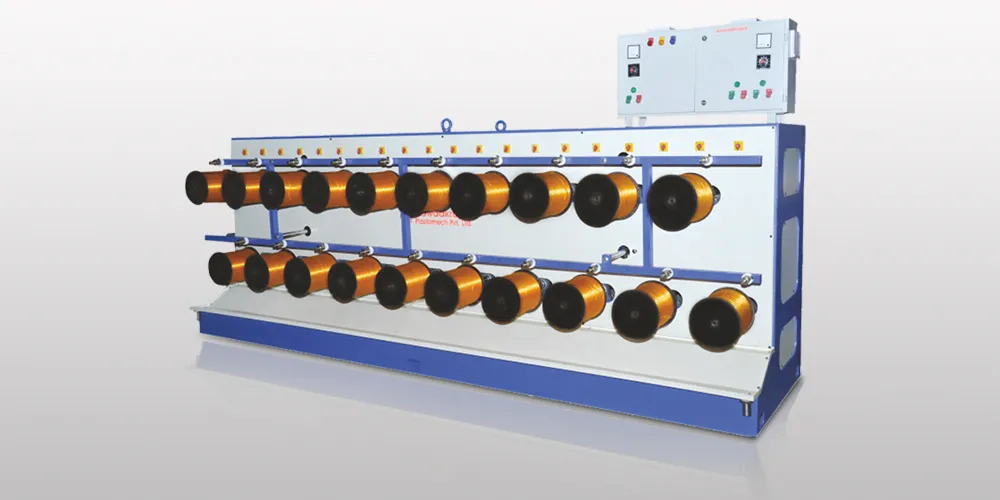

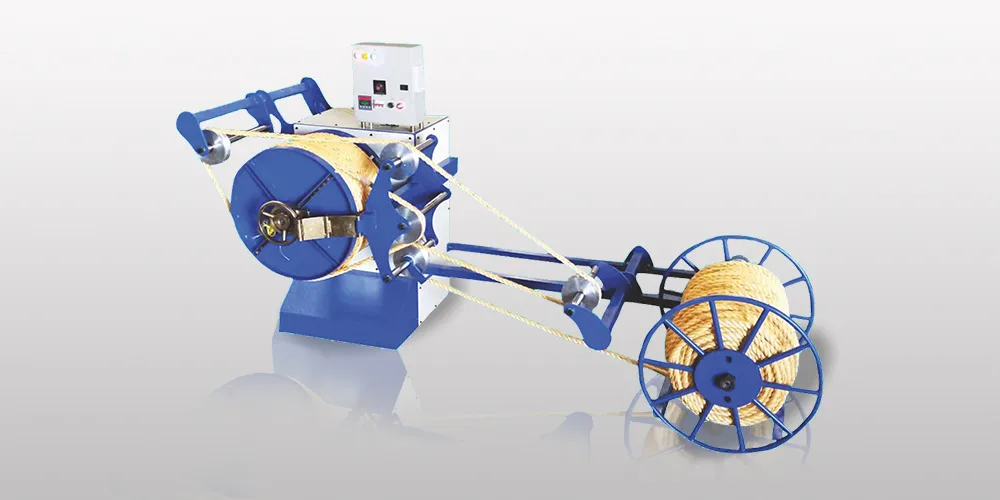

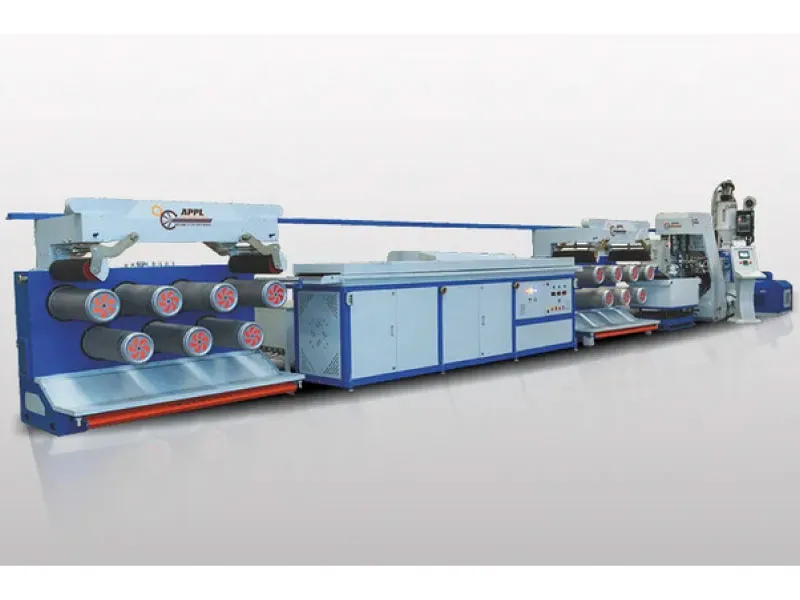

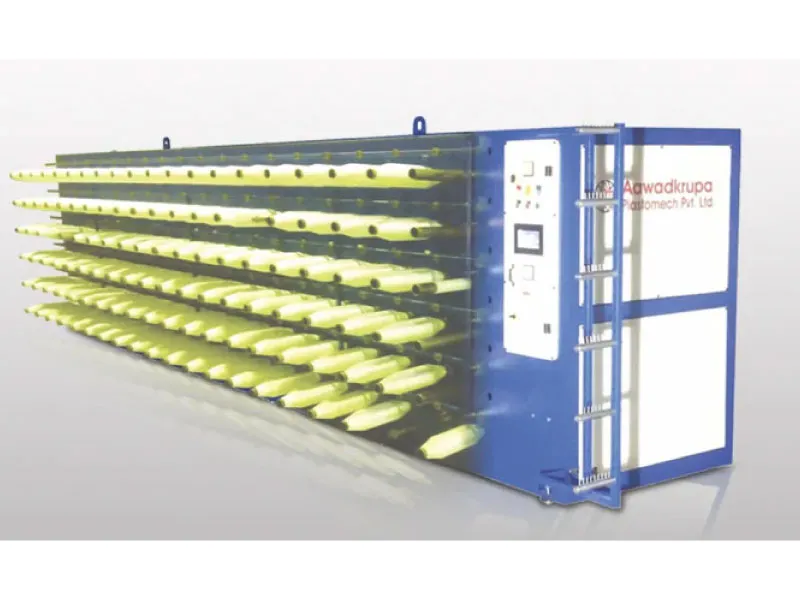

Aawadkrupa Plastomech Pvt. Ltd. is a trusted and leading manufacturer and exporter of Mono Danline Extrusion Plants, offering advanced and reliable solutions for rope production. Our extrusion plants are specially designed to produce high-quality monofilament ropes using materials like high-density polyethylene (HDPE) or polypropylene (PP), known for their strength, durability, and resistance to weather and abrasion.

These monofilament ropes are widely used in various industries such as agriculture, fishing, marine, shipping, construction, and transportation. They are ideal for heavy-duty applications like mooring, towing, lifting, and securing loads. Our Mono Danline Extrusion Plants are engineered for smooth operation, high efficiency, and consistent output.

With a strong production capacity ranging from 1000 to 2000 tons per year, we ensure timely delivery and top performance. At Aawadkrupa Plastomech, we are committed to quality, innovation, and customer satisfaction—making us a preferred choice for businesses looking to boost their rope manufacturing capabilities.