Scan the QR to call

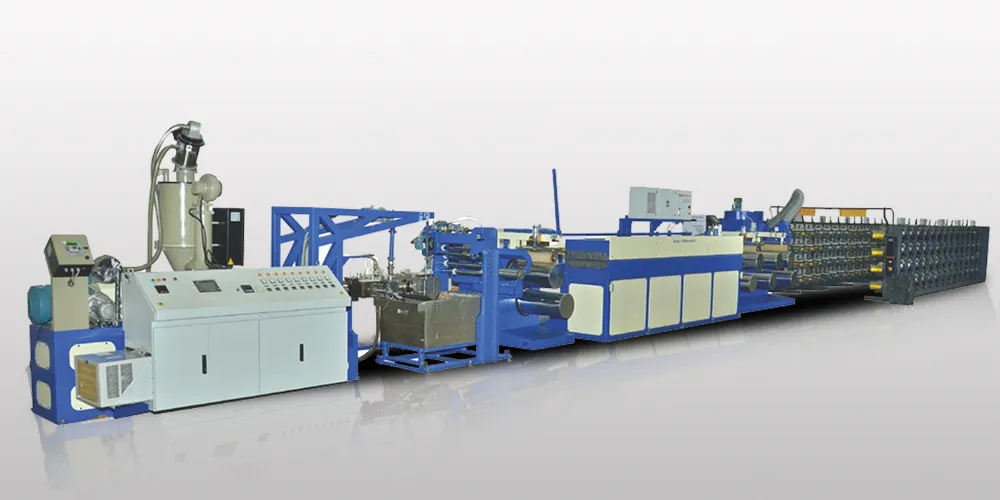

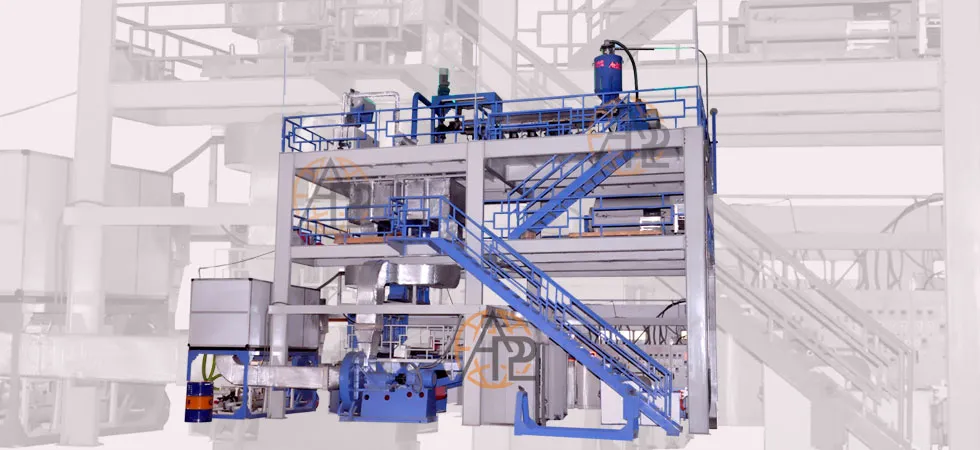

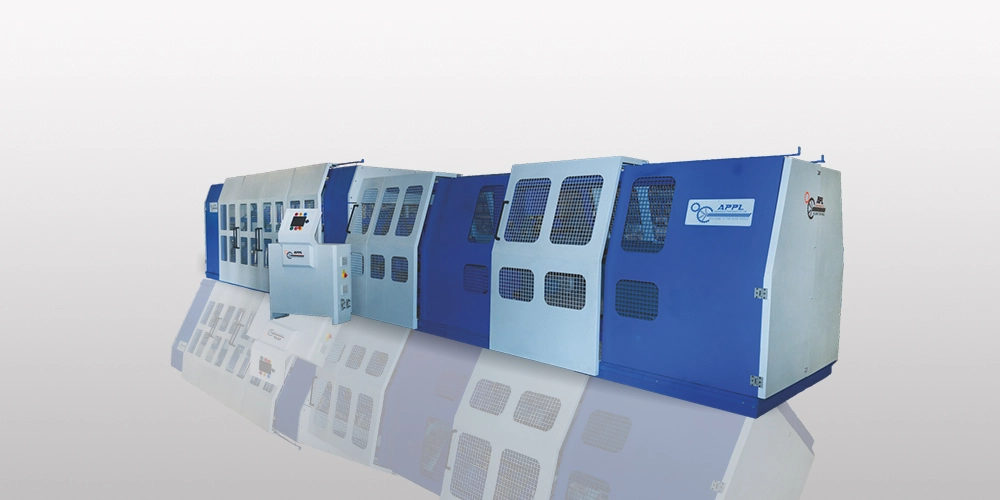

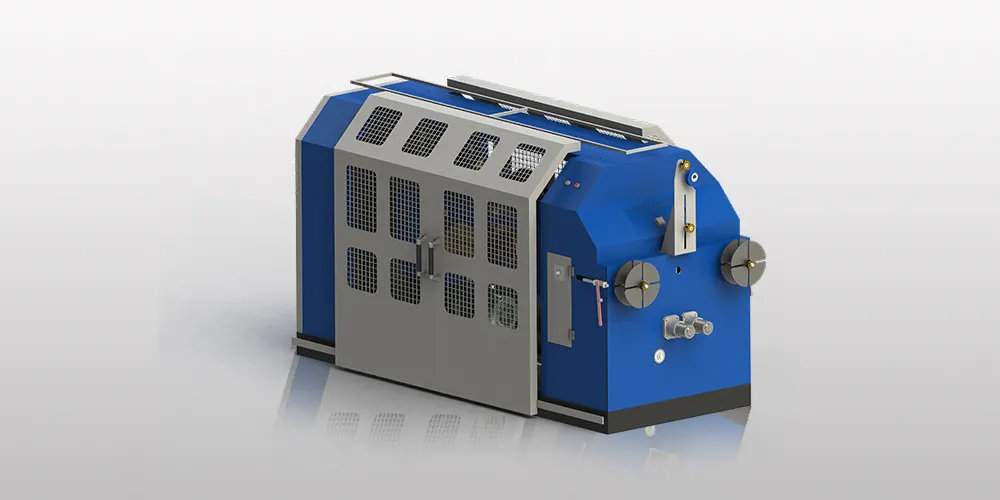

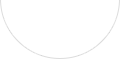

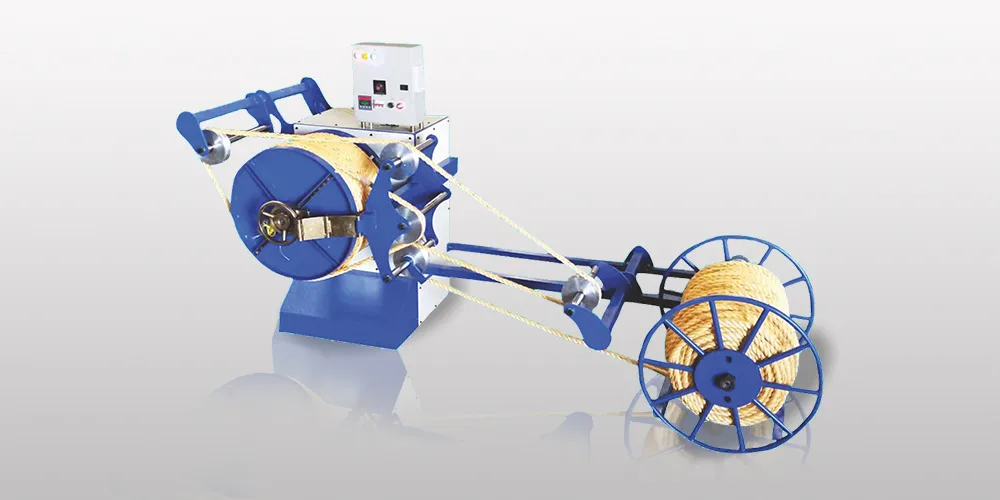

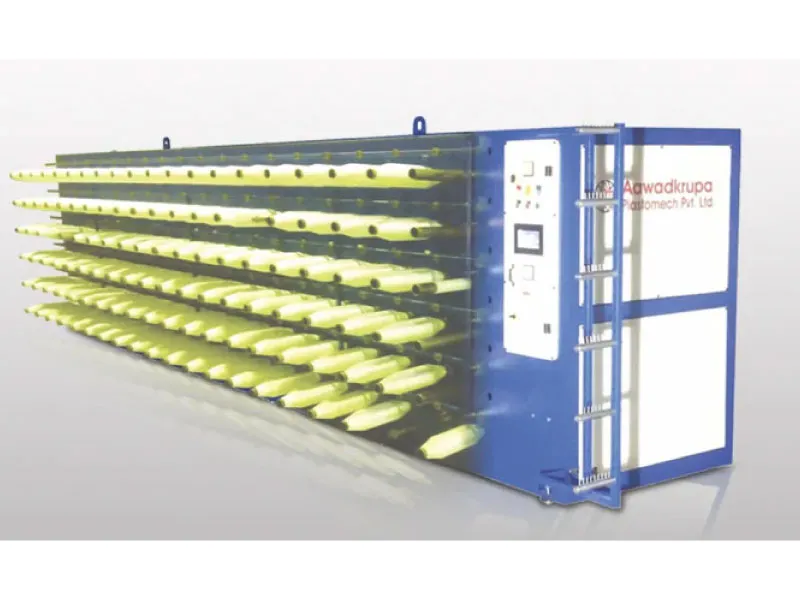

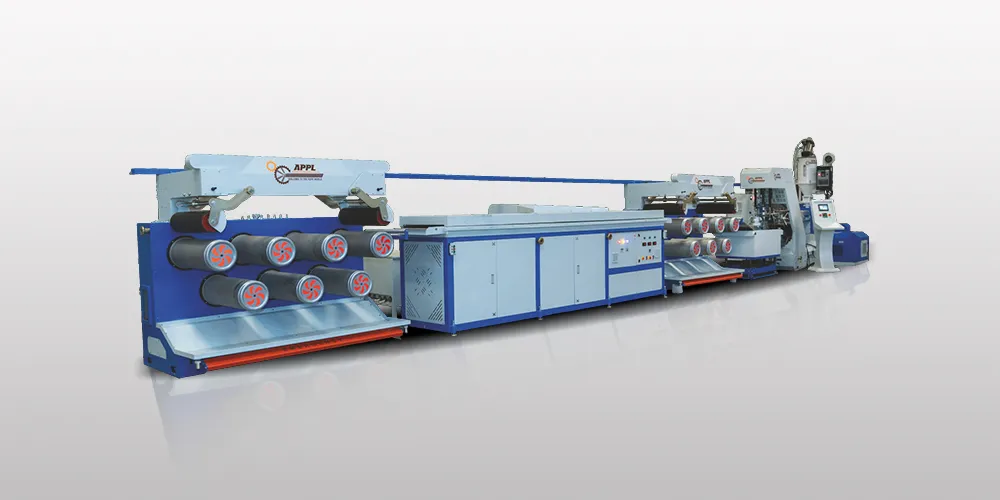

Monofilament Extrusion Plant

Leading Monofilament Extrusion Plant Manufacturer & Exporter

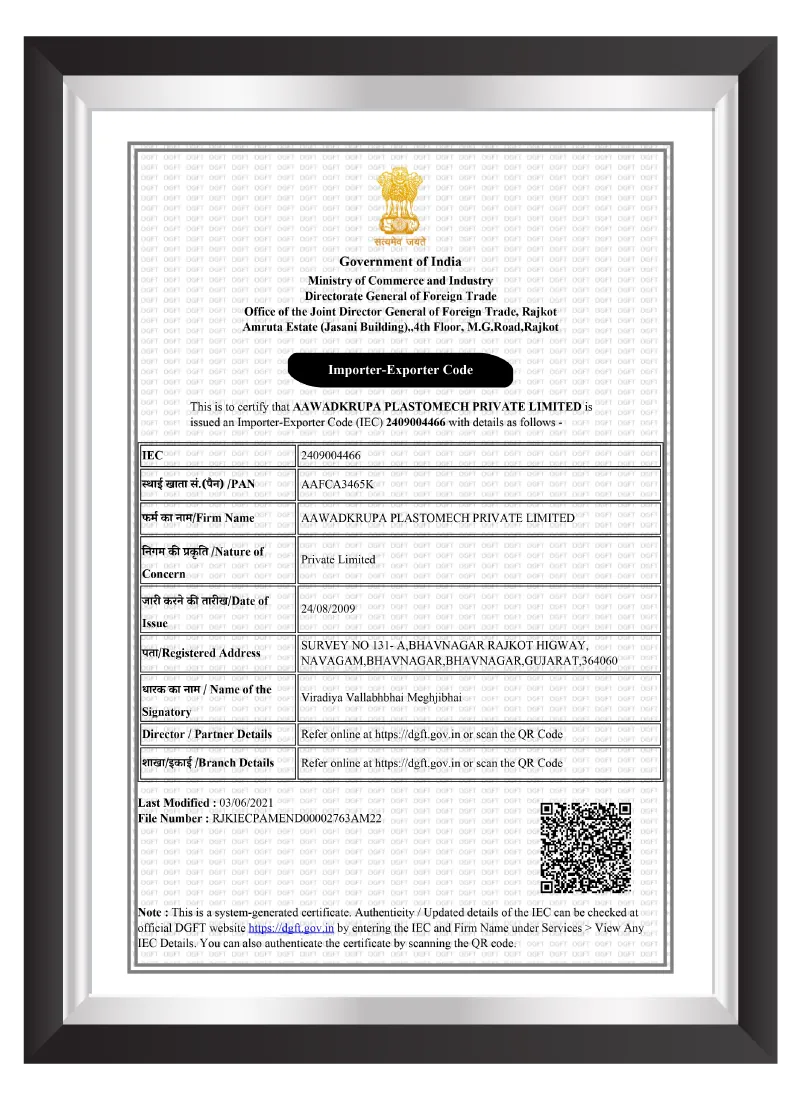

At Aawadkrupa Plastomech Pvt. Ltd., we take pride in being a leading Manufacturer & Exporter of Monofilament Extrusion Plants. Our innovative facilities and advanced technology qualify us to produce high-quality machinery that meets the needs of our customers worldwide.

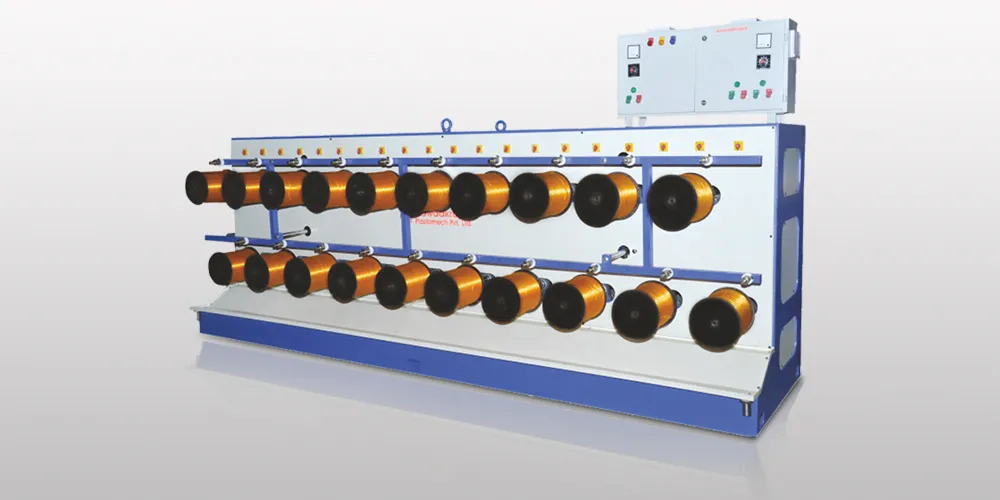

Our Monofilament Extrusion Plants are designed to provide high-quality and secure production of monofilament fibers used in a variety of applications such as fishing nets, ropes, brushes, and more. With a focus on precision engineering and superior performance, our machines are built to deliver consistent output with minimal downtime.

We understand the importance of quality and reliability in manufacturing processes, which is why our Monofilament Extrusion Plants are built to the highest standards to reduce specific durability and longevity. So that you are looking to improve your existing production line or start a new venture, our Monofilament Extrusion Plants are the perfect solution for your extrusion needs.

Description

| SR. NO. | MODEL NO. | SIZE (mm) | PRODUCTION (Kgs/Hrs) |

|---|---|---|---|

| 1 | APPL / MF – 55 AC | 55 | 37 |

| 2 | APPL / MF – 65 AC | 65 | 60 |

| 3 | APPL / MF – 75 AC | 75 | 120 |

| 4 | APPL / MF – 90 AC | 90 | 150 |

| 5 | APPL / MF – 100AC | 100 | 200 |

| 6 | APPL / MF – 80 GF | 80 | 250 (High-speed Model) |

| 7 | APPL / MF – 110AC | 110 | 250 |

| 8 | APPL / MF – 120AC | 120 | 350 |

| Twine Die | |||

| 9 | APPL / MF – 75 AC | 75 | 120 |

| 10 | APPL / MF – 90 AC | 90 | 150 |

| 11 | APPL / MF – 110 AC | 110 | 250 |

Applications

Product Video

Advantages

- 1. High Productivity: Our Monofilament Extrusion Plants are designed for well-organized and high-speed production, enabling you to increase your output and meet market demands effectively.

- 2. Quality Output: Our machines are built with precision engineering to ensure consistent and high-quality monofilament fibers, meeting industry standards and customer expectations.

- 3. Customization Options: We offer customization options to adapt our Monofilament Extrusion Plants to your specific requirements, ensuring that the machinery meets your unique production needs.

- 4. Energy Efficiency: Our Monofilament Extrusion Plants are designed to optimize energy consumption, helping you reduce operational costs and improve sustainability.

- 5. Durability and Reliability: Built with high-quality materials and components, our machines are durable and reliable, offering long-term performance with minimal downtime.

- 6. Technical Support: We provide comprehensive technical support and after-sales service to ensure that your Monofilament Extrusion Plant operates smoothly and efficiently.

Request for a Quotation

COMPANY PROFILE

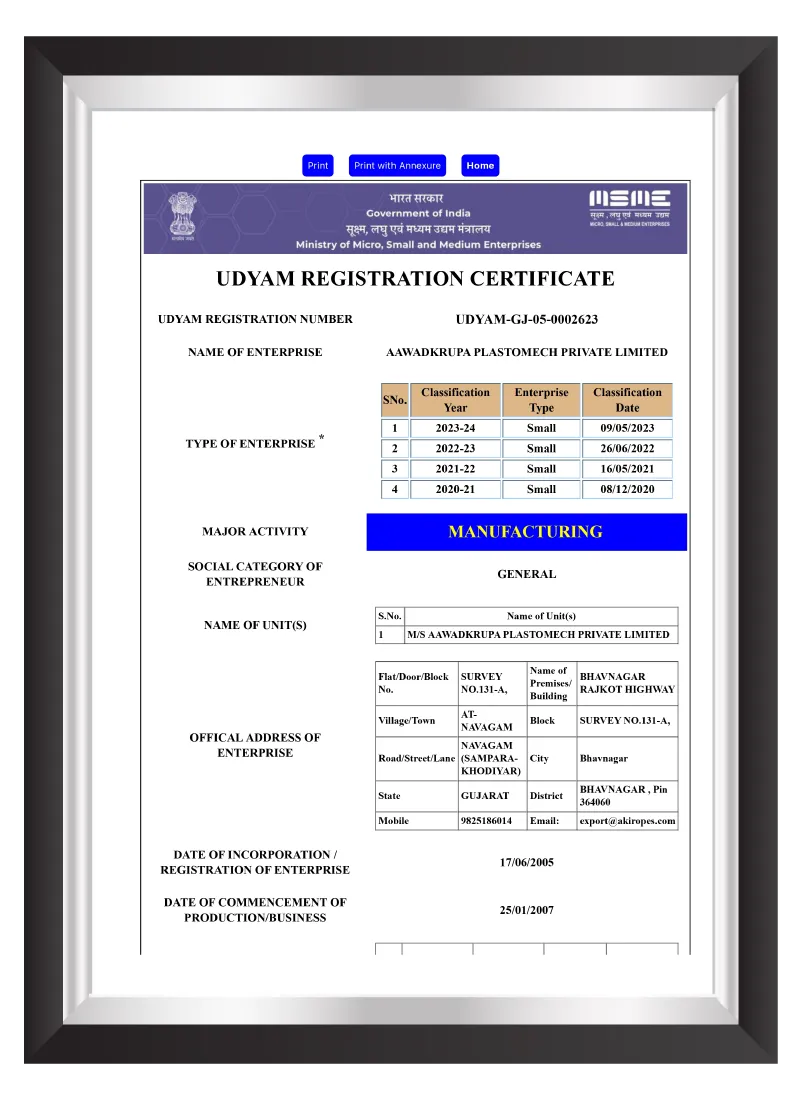

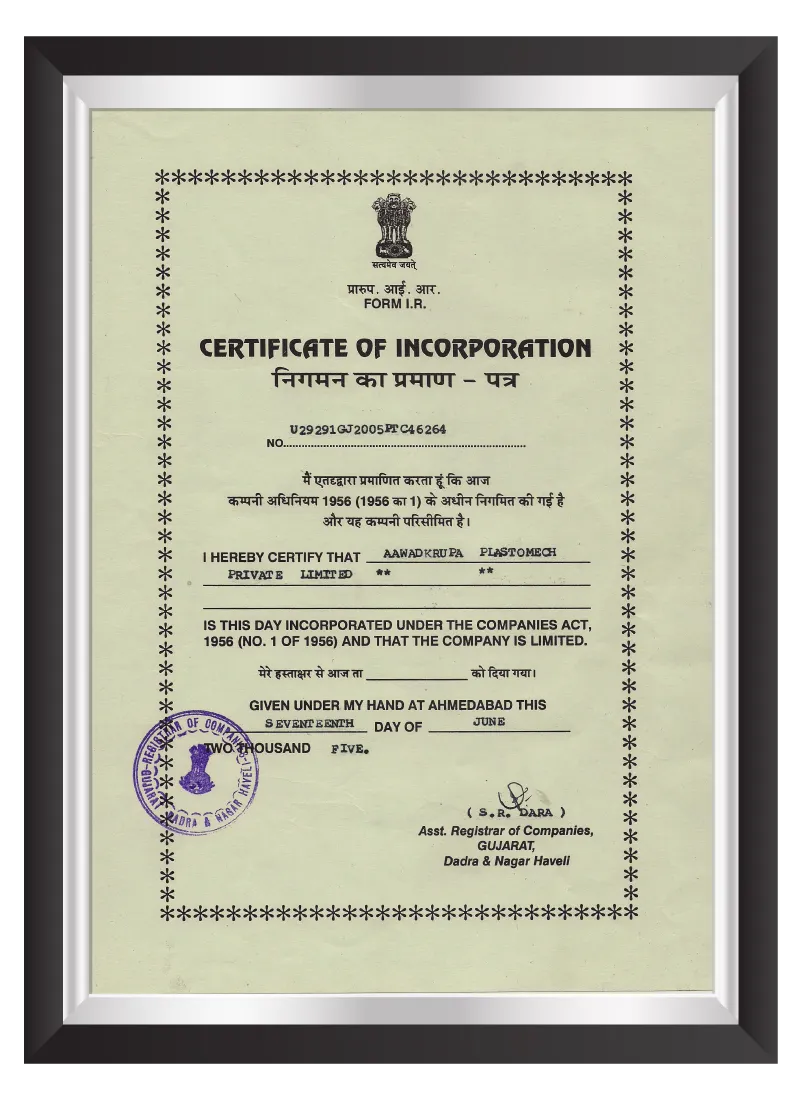

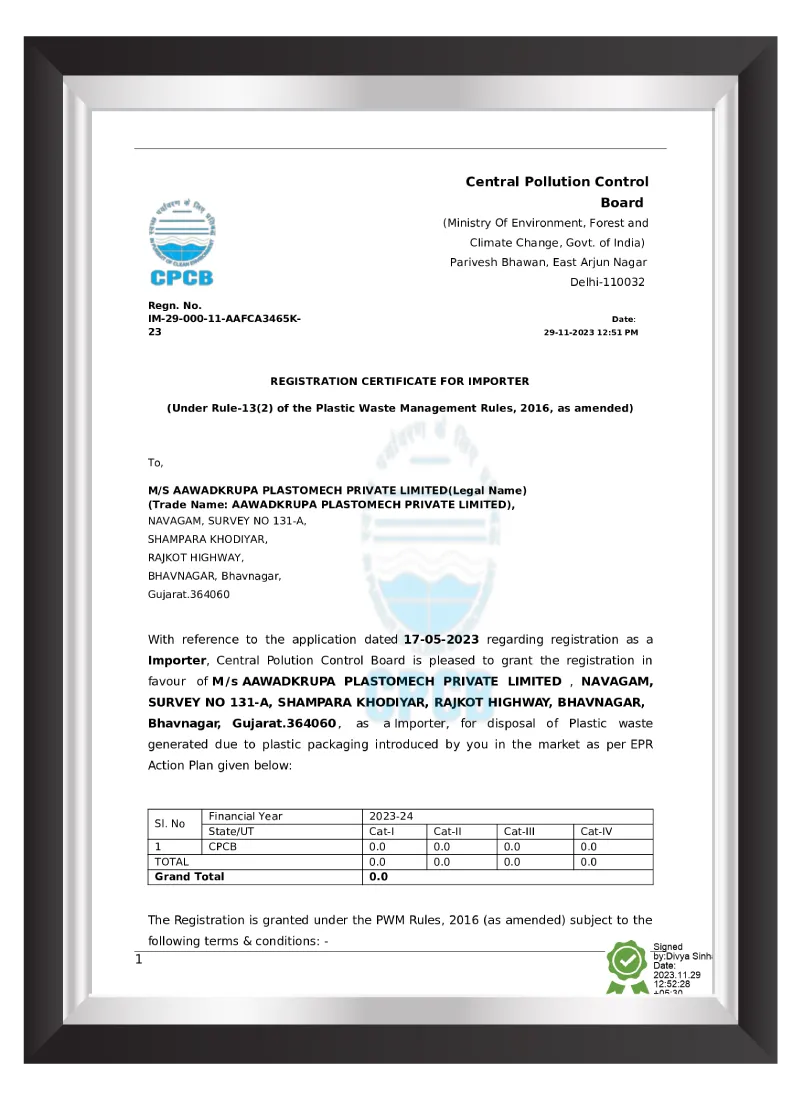

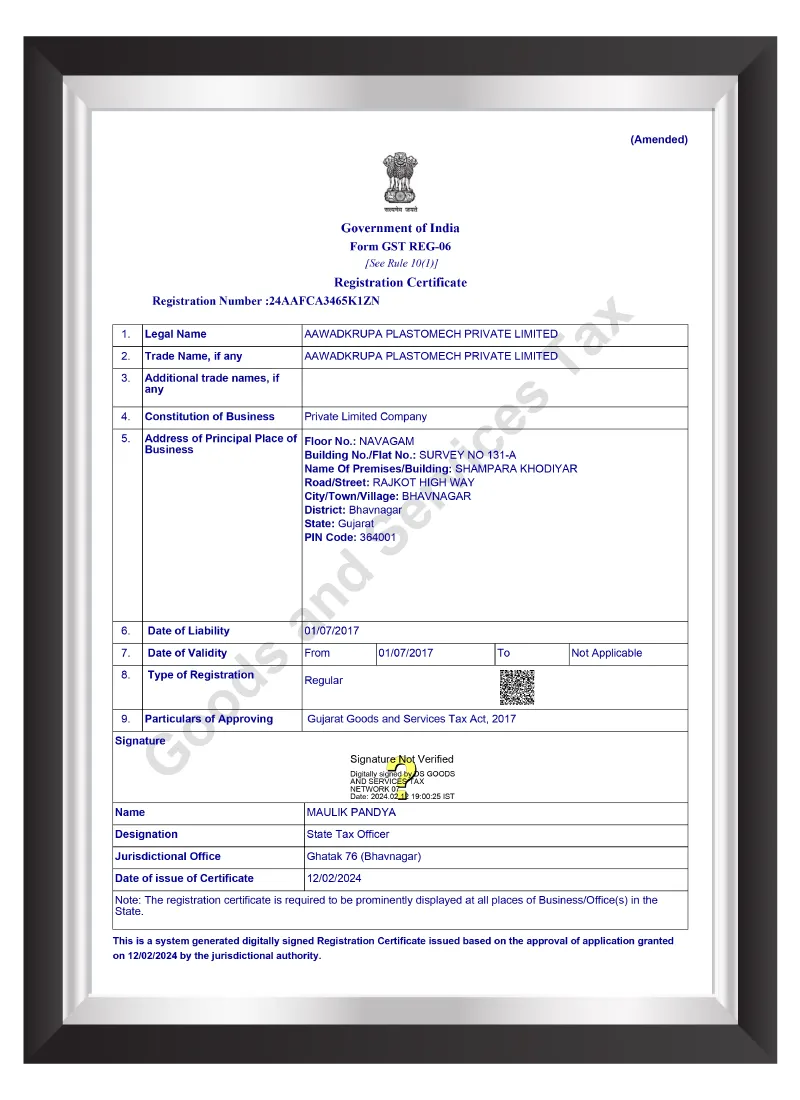

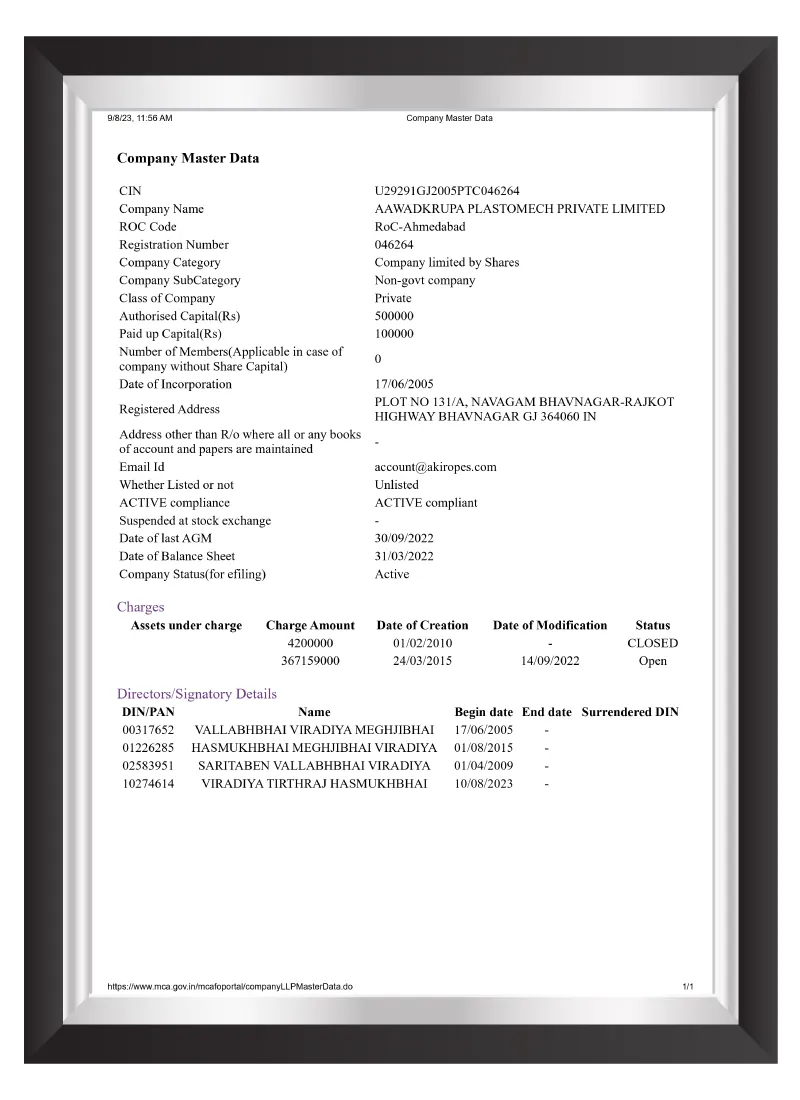

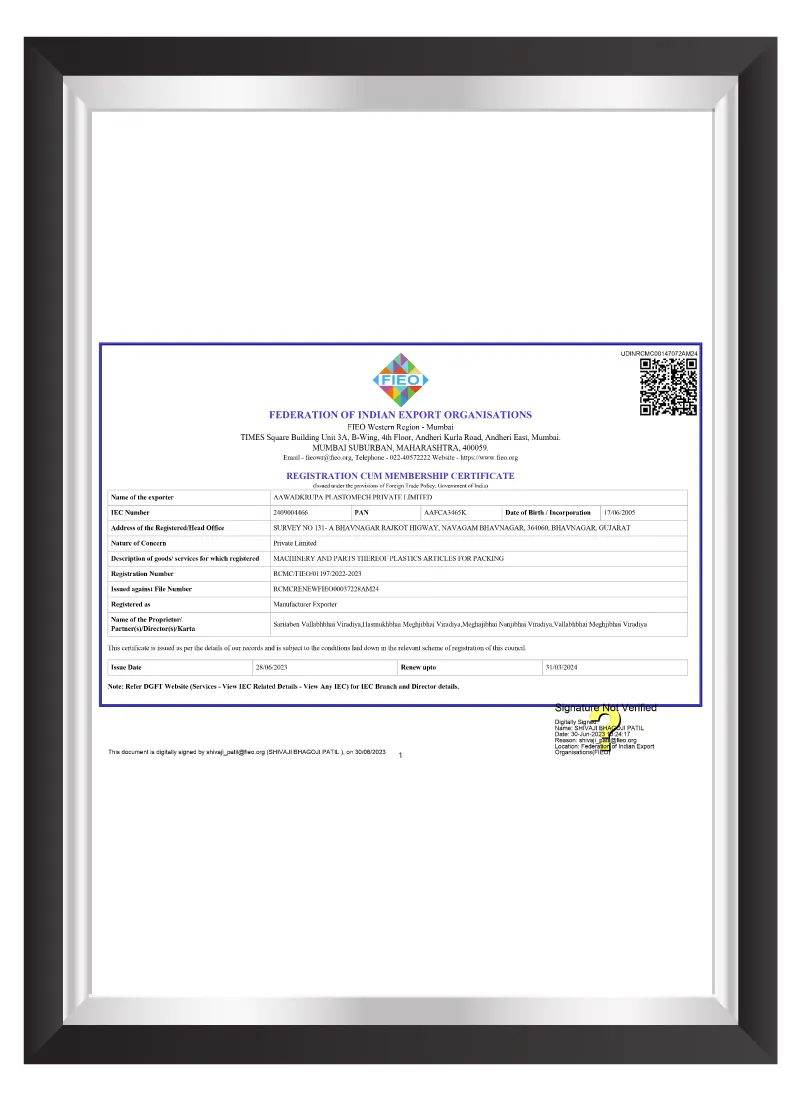

Aawadkrupa Plastomech Pvt. Ltd. is pioneer and front runner as a Manufacturer & Exporter of wide range of "Plastic Extrusion Plants, Ring Twisters & Rope Making Machineries" in India since year 1996 by employing young ambitious professionally managed team of engineers. In the year 2000 company started manufacturing of monofilament extrusion plant & the entire turnkey project for plastic rope factory. Then after we established another company named "Aawadkrupa Plastomech Pvt. Ltd.", in year 2005. As the neighbouring factory of "Aawadkrupa Plastomech" by expanding our production capacity & manufacturing facilities.The company today is an ISO 9001 : 2015 , 45001 : 2018 , CE & One Star Export House certified

Experience in Industry

We Export

FAQ's

-

What is monofilament extrusion?Monofilament extrusion is a process used to make continuous strands of polymeric material for a variety of consumer and industrial products. Both one and two polymer systems called co-extrusion or bicomponent extrusion are widely used. Synthetic monofilament fibers are produced by extruding a melted polymer through small spinneret holes. This process is well known and is broadly applied in industry. The preparation, melting, and extrusion of the polymer are similar to those used for film blowing, die casting, and various fiber spinning processes. However, for higher tex fibers (diameters of > 100 microns) the fiber processing is unique and is similar to slit film fiber processing (Hans A. Krassig, 1984). In the case of low tex monofilaments, the fiber processing steps are similar to the production of standard industrial multi-filament fibers.

-

What material is monofilament?One of the fluoropolymer products we manufacture for many different industries is monofilament fiber. In a nutshell, monofilament is a single filament of synthetic fiber. Monofilament is made by melting and mixing polymers. The polymer mixture is then extruded through holes, creating lines of various thickness. While it used in many applications now, many people are introduced to monofilament fiber the first time they go fishing.

-

What is the use of monofilament fabric?It is the net in the form of fabric primarily used for the purpose of wet filtration in industries like textile and spinning, chemical, printing, rubber & various others.

RELATED PRODUCTS

RELATED BLOGS

Best Rope Making Machine Manufacturer in India

A rope making machine is a machine that is used to manufacture rope....

Best Manufacturer of Bobbin winder in India

People who work in the sewing, knitting, weaving, spinning, lacemaking....

Best Manufacturer of Ring Twister in India

We look at effective way, to keep trespassers away and to protect your plot....

Best Manufacturer of Endless Rope Making Machine in India

We are eager to create devices that will benefit and meet the demands of our....

Best Manufacturer of Rope Coiling Machine in India

We are a leading manufacturer of high-quality rope coiling machine in India....

Monofilament Extrusion Plant Manufacturer in India

We are a renowned manufacturer and exporter of a wide selection of extrusion....

Best Manufacturer of Plastic Yarn Grinding Machine in India

Plastic strands are ground and recycled into useable products using plastic....

Best Manufacturer of Pineapple Winder in India

We were able to export and produce India's No. 1 and High Performance Pineapple Winder....

Our Global Presence

Algeria

Australia

Brazil

Chad

Chile

Durban

Egypt

Ethiopia

Indonesia

Ireland

Kenya

Malaysia

Mauritania

Mexico

Morocco

New Zealand

Nigeria

Peru

Romania

Russia

Saudi Arabia

Sri Lanka

Tanzania

Tunisia

Turkey

UAE

USA

Zambia

Zimbabwe

We Export To

USA | China | Japan | South Korea | Taiwan | Singapore | Malaysia | Thailand | Indonesia | Vietnam | Philippines | Sri Lanka | Bangladesh | Saudi Arabia | UAE | Turkey | Germany | France | United Kingdom | Italy | Spain | Netherlands | Poland | Switzerland | Sweden | Belgium | Austria | Norway | Denmark | Finland | Czech Republic | Hungary | Slovakia | Greece | Portugal | Romania | Bulgaria | Canada | Mexico | Brazil | Argentina | Chile | Colombia | Peru | South Africa | Nigeria | Egypt | Kenya | Algeria | Morocco | Tunisia | Ghana | Australia | New Zealand | Russia | Ukraine | Belarus | Kazakhstan | Uzbekistan | Iran | Qatar | Oman | Kuwait | Venezuela | Bolivia | Paraguay | Uruguay | Ethiopia | Tanzania | Zambia | Angola