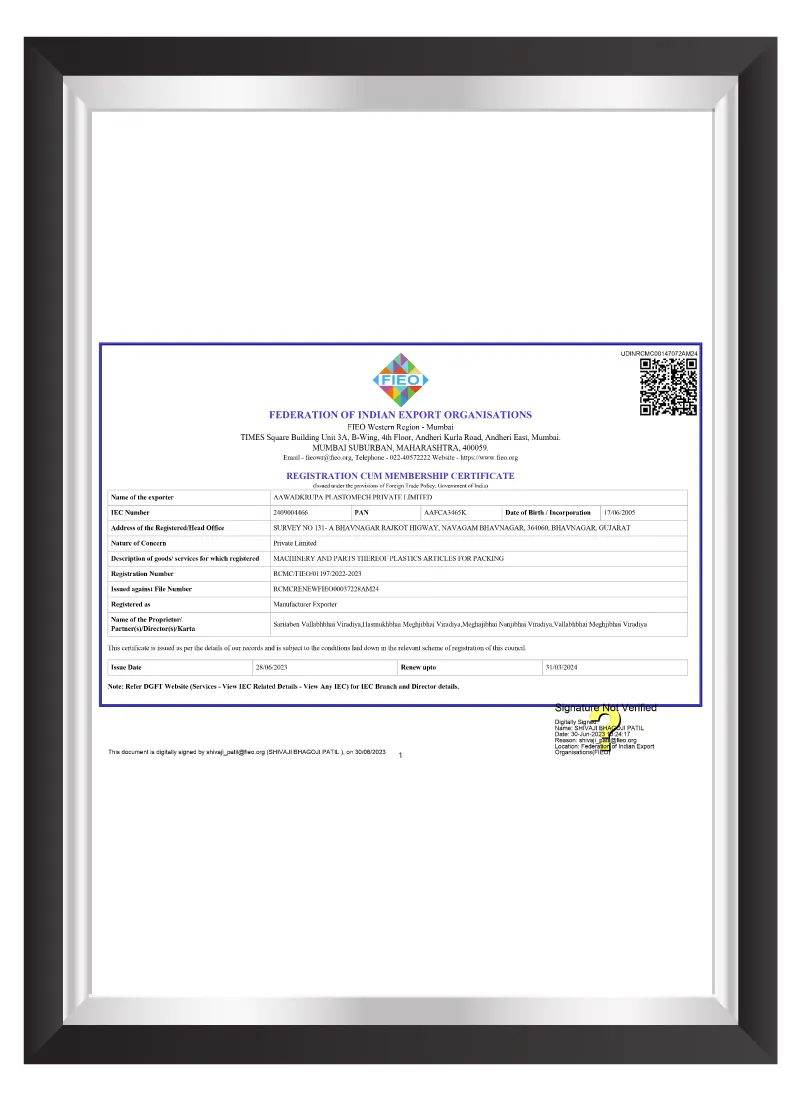

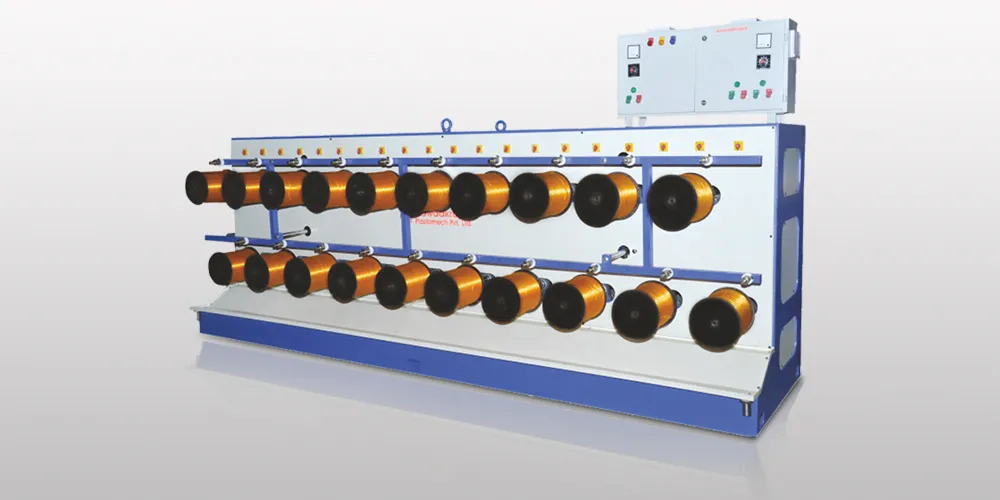

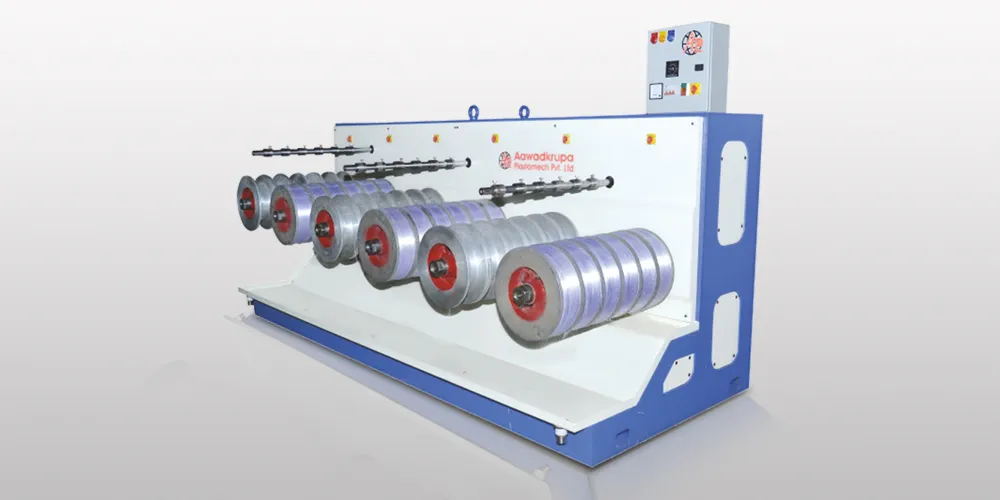

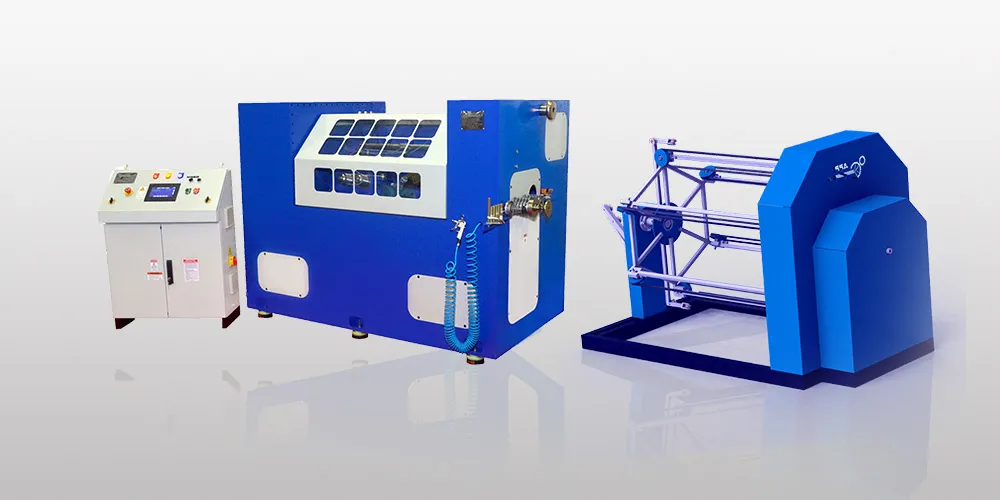

At Aawadkrupa Plastomech Pvt. Ltd., we are proud to offer our top-quality Inflow Twister Machine, which is designed for twisting and creating cross-wound packages of flat filaments. This machine is important for producing strong and durable threads from materials like cotton, wool, silk, and synthetic fibers. It is commonly used in conjunction with PP Fibrillated Tape Extrusion Lines to make Baler Twine, perfect for various textile applications.

Our Inflow Twister Machine works by feeding yarns from different bobbins through rollers that control tension and guide them into the twisting zone. Here, rotating spindles twist the yarns together at high speeds, resulting in a superior thread quality. The twisted yarn is then neatly wound onto bobbins or cones for storage or more processing.

Factors that can impact the performance of our Inflow Twister Machine include the quality of the yarns, machine speed and tension settings, environmental conditions like temperature and humidity, and regular maintenance. Your trusted Aawadkrupa Plastomech Pvt. Ltd. for reliable and efficient Inflow Twister Machine that improve your textile production processes.