In the dynamic world of manufacturing, precision and performance define the success of any product. One area where this is particularly evident is in the production of high-performance ropes, where consistency, strength, and durability are critical. At the heart of this process lies a remarkable piece of machinery — the Monofilament Extrusion Plant. For companies aiming to produce top-tier ropes for commercial, industrial, or marine applications, investing in a robust Monofilament Extrusion Plant is a strategic decision.

At Aawadkrupa Plastomech Pvt. Ltd., we specialize in the manufacturing and export of world-class Monofilament Extrusion Plants. Our machines are designed for versatility, productivity, and exceptional performance, delivering uniform monofilament fibers suitable for applications ranging from fishing nets and ropes to brushes, synthetic textiles, and industrial filters.

What is a Monofilament Extrusion Plant?

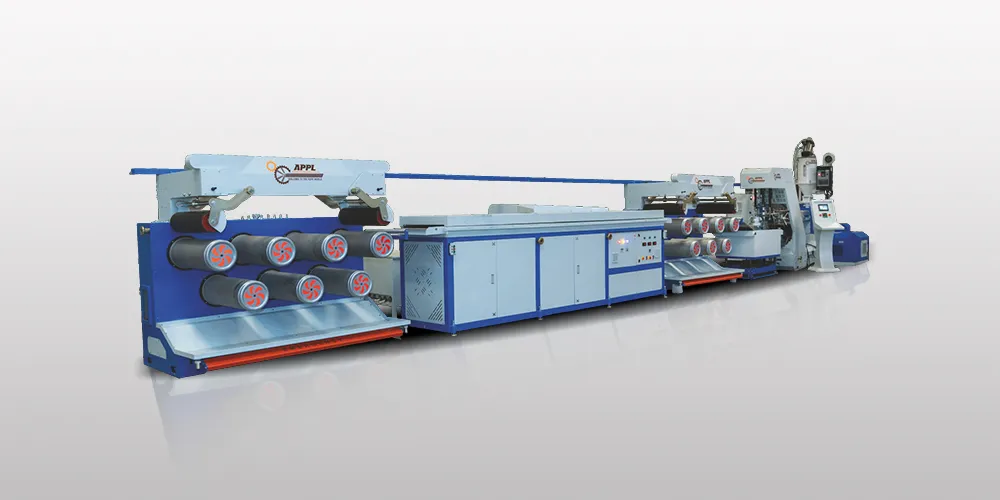

A Monofilament Extrusion Plant is a sophisticated industrial machine used to produce single-strand polymer fibers, commonly known as monofilaments. These fibers are made from polymers such as polypropylene (PP), high-density polyethylene (HDPE), or nylon, and are widely used in the production of ropes, nets, and brushes. The extrusion process involves melting the raw polymer, forcing it through a precision die to form strands, and then cooling and stretching the strands to the desired thickness and strength.

Importance in Rope Manufacturing

High-performance ropes are used in demanding environments like shipping, agriculture, construction, and industrial lifting. These applications require ropes that are strong, abrasion-resistant, UV-stable, and reliable over long periods. The quality of the monofilament fiber directly influences the rope’s durability and performance. A well-engineered Monofilament Extrusion Plant ensures uniformity in the fiber’s cross-section, controlled molecular orientation, and optimized physical properties. This leads to ropes that not only perform better but also last longer, withstanding harsh environmental conditions and mechanical stresses.

Key Components of a Monofilament Extrusion Plant

At Aawadkrupa Plastomech Pvt. Ltd., our Monofilament Extrusion Plants are constructed using premium-grade materials and are engineered for continuous, uninterrupted operation. The key components of our systems include:

- Extruder Unit: Equipped with high-precision screw and barrel to melt and homogenize the polymer.

- Spin Die Head: Delivers uniform strands through multi-hole dies.

- Cooling Tank: Cools the strands evenly to solidify them while maintaining dimensional accuracy.

- Stretching Unit: Aligns polymer molecules to increase tensile strength.

- Winder/Take-up Unit: Winds the monofilament into rolls for easy handling and further processing.

Each of these parts is designed to optimize production efficiency, minimize maintenance, and provide excellent control over monofilament properties.

Advantages of Using Monofilament Extrusion Plants

- Consistent Quality Output

With a reliable Monofilament Extrusion Plant, manufacturers can produce uniform, high-quality fibers every cycle. This leads to better end-products and fewer defects. - High Production Efficiency

Modern extrusion plants offer higher output with lower energy consumption. Features such as synchronized drives and precision temperature controls boost efficiency. - Wide Application Flexibility

From lightweight fishing lines to ultra-strong industrial ropes, Monofilament Extrusion Plants support a wide range of applications. - Enhanced Durability of Final Products

The tensile strength, chemical resistance, and flexibility of the monofilament contribute significantly to the final rope’s performance. - Customization and Scalability

We offer custom configurations in terms of die shapes, cooling lengths, line speed, and spool sizes — adapting the plant to your specific production needs.

Applications of Monofilament Fibers

- Rope Manufacturing: Durable and UV-resistant monofilaments are used to make marine, industrial, and agricultural ropes

- Fishing Nets: Lightweight, corrosion-proof monofilaments are ideal for saltwater environments

- Brushes and Brooms: From household to industrial brushes, monofilaments offer flexibility and durability

- Synthetic Fabrics: Certain monofilaments are used in filtration fabrics and geotextiles

The production of these items requires high precision, and only a robust Monofilament Extrusion Plant can meet those requirements consistently.

Global Reach and Customer Trust

Our clients span across 60+ countries, trusting Aawadkrupa Plastomech Pvt. Ltd. for consistent quality, timely service, and robust machinery. We understand the international standards and offer complete after-sales support, technical training, and installation guidance.

Why Choose Us

Aawadkrupa Plastomech Pvt. Ltd. stands as a trusted name in the industry for delivering world-class Monofilament Extrusion Plants. Our commitment to precision engineering, customer-centric approach, and continuous innovation set us apart. With years of industry experience and a strong focus on quality, our machines are designed to empower businesses in the rope manufacturing and monofilament industry. We are dedicated to helping our clients grow through dependable equipment, global support, and unmatched technical knowledge. Choosing Aawadkrupa Plastomech Pvt. Ltd. means choosing performance, reliability, and long-term success.

Conclusion

The backbone of high-performance rope manufacturing is a reliable Monofilament Extrusion Plant. From superior tensile strength to consistent fiber diameter, the quality of extrusion directly affects the rope’s end-use performance. Whether you’re supplying fishing nets, industrial ropes, or household brush bristles, investing in the right extrusion plant is essential. Backed by advanced technology and trusted by global manufacturers, Aawadkrupa Plastomech Pvt. Ltd. is your partner in growth. Our systems are built for productivity, precision, and longevity—just what you need to lead in the competitive rope industry.

Want to learn how Monofilament Extrusion Plants can transform your rope production business? Call Aawadkrupa Plastomech Pvt. Ltd. at +91 9510186014 or email us at info@akiropes.com for more detailed information and expert guidance.