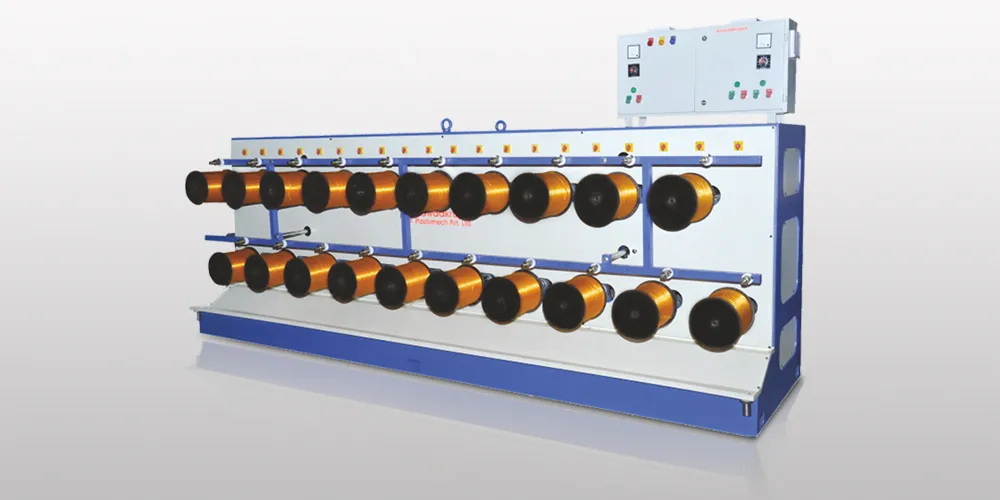

Aawadkrupa Plastomech is pioneer and front runner as a Manufacturer & Exporter of world-class machines designed to revolutionize the textile industry. One of our standout products is the Bobbin Winder Machine, a vital tool for modern textile manufacturing. Our Bobbin Winder Machine serves an indispensable role in winding thread or yarn onto bobbins or spools, which are crucial for a variety of textile applications, such as sewing, embroidery, and weaving.

When it comes to ensuring the smooth operation of textile production, precision is key. This blog will guide you through the essential features to look for in a modern Bobbin Winder Machine, and explain why choosing the right one can drastically improve your manufacturing process.

Key Features to Look for in a Modern Bobbin Winder Machine

A modern Bobbin Winder Machine needs to combine precision, speed, and adaptability. Here are the essential features that make our machines stand out:

Precision Winding for Quality Output

At the heart of any Bobbin Winder Machine is its ability to produce high-quality, evenly wound bobbins or spools. The winding mechanism must be precise to prevent thread breakage or tension issues during subsequent textile processes like sewing or weaving.

Aawadkrupa Plastomech’s Bobbin Winder Machine ensures consistent, smooth winding with minimal operator intervention. Our machines use specialized rollers and spindles that deliver high-quality results with each cycle. This precision minimizes defects and maximizes the quality of your final product, whether you’re working with cotton, polyester, nylon, or any other thread material.

Increased Speed and Productivity

In a competitive industry like textiles, speed is a major factor in maintaining production efficiency. A modern Bobbin Winder Machine must be capable of winding a large number of bobbins in a short period of time, helping manufacturers meet high-demand orders.

Our Bobbin Winder Machine is designed to wind at optimal speeds without compromising quality, resulting in higher throughput. This efficiency allows manufacturers to process more materials, cut down on downtime, and ultimately increase their production capacity.

Versatility Across Materials

Not all yarns and threads are the same, and the Bobbin Winder Machine must be versatile enough to handle different types of materials. Whether it’s fine silk thread for delicate embroidery or thick yarn for industrial weaving, your winding machine needs to adapt to various materials.

Aawadkrupa Plastomech’s Bobbin Winder Machine can easily handle a wide range of thread types, including cotton, silk, nylon, polyester, and more. This flexibility makes it a perfect choice for diverse textile applications, reducing the need for multiple machines to handle different material types.

Automatic Tension Control

Proper tension control is crucial for achieving perfectly wound bobbins. Too much tension can cause the thread to break, while too little tension can lead to messy, uneven bobbins. Modern Bobbin Winder Machines come equipped with automatic tension control mechanisms that adjust the tension during the winding process.

Our Bobbin Winder Machine is equipped with advanced tension control systems that ensure a consistent, even winding process regardless of thread type or thickness. This feature guarantees that your bobbins maintain optimal performance, preventing future issues in downstream textile processes.

Ease of Operation and Maintenance

For a machine to truly improve production efficiency, it must be user-friendly and easy to maintain. Complex machines with steep learning curves can slow down your team and create unnecessary bottlenecks.

Aawadkrupa Plastomech’s Bobbin Winder Machine is designed with simplicity in mind. The intuitive interface allows operators to easily set parameters like winding speed and tension. Plus, the machine’s minimal maintenance needs ensure less downtime, keeping your production process running smoothly and efficiently.

Durable and Long-Lasting Construction

A Bobbin Winder Machine operates in a high-demand environment, so it must be built to last. Choosing a machine made from high-quality materials ensures that it will withstand continuous use without frequent breakdowns or repairs.

Our Bobbin Winder Machine is made from durable, high-quality materials that ensure longevity. Designed for long-term use, it will continue to perform optimally even in demanding environments, making it a reliable investment for your textile manufacturing needs.

Why Choose Aawadkrupa Plastomech Pvt. Ltd.?

As a trusted Bobbin Winder Machine Manufacturer, Aawadkrupa Plastomech Pvt. Ltd. leads the way in providing innovative solutions for the textile industry. We combine years of industry experience with cutting-edge technology to deliver machinery that enhances productivity, reduces costs, and ensures superior quality in every batch.

What sets us apart from other Bobbin Winder Machine Manufacturers is our commitment to understanding our customers’ needs and offering tailor-made solutions. Our machines are engineered to perform at the highest levels, offering advanced features that boost efficiency and improve the quality of your final products.

Conclusion

A modern Bobbin Winder Machine is a game-changer in the textile industry, enhancing efficiency, precision, and overall product quality. When selecting a Bobbin Winder Machine Manufacturer, it is crucial to focus on features like precision winding, speed, versatility, automatic tension control, and ease of operation.

At Aawadkrupa Plastomech Pvt. Ltd., we offer the latest innovations in Bobbin Winder Machines, backed by decades of expertise and customer-focused service. Our machines are designed to meet the demands of modern textile production, helping you stay ahead of the competition.

For more details or to inquire about our Bobbin Winder Machine, feel free to call us at +919510186014 or email us at info@akiropes.com. We are always happy to help you make the right investment in your textile production process!