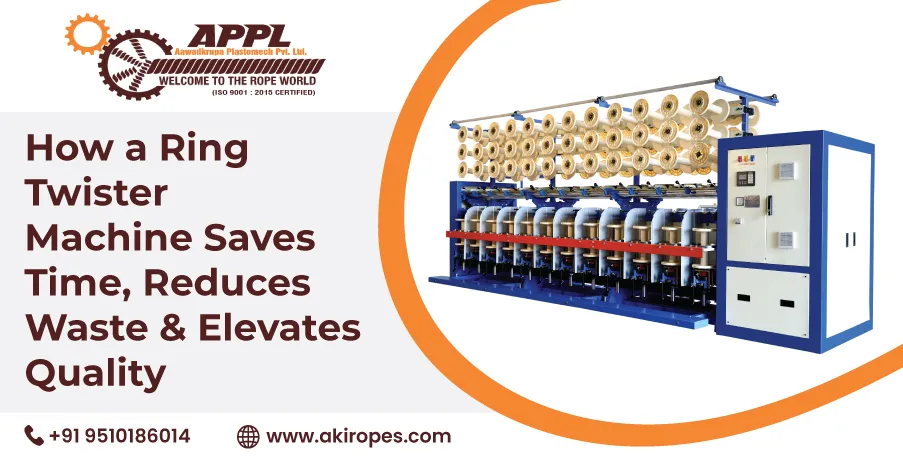

In modern rope manufacturing, efficiency, precision, and product quality are key factors that define a company’s success. A Ring Twister Machine plays a pivotal role in achieving these goals by automating the twisting process, reducing manual labor, and producing consistently high-quality ropes. At Aawadkrupa Plastomech Pvt. Ltd., we provide state-of-the-art ring twister machines designed to meet the rigorous demands of industrial rope production.

What is a Ring Twister Machine?

A Ring Twister Machine is a specialized industrial device used to twist multiple strands of fibers into ropes of various sizes and strengths. These machines are engineered for precision, durability, and high-speed performance, making them indispensable for modern rope manufacturing.

Key features include:

- Adjustable twisting speeds for different rope thicknesses

- High-capacity output to handle bulk production

- Durable construction for long-term use

- Compatibility with various fiber types, including natural and synthetic materials

The ring twister machine ensures uniformity in rope structure, enhancing both strength and flexibility.

Benefits of a Ring Twister Machine

Time Efficiency

A ring twister machine automates the twisting process, significantly reducing production time compared to manual methods. High-speed models can produce large quantities of rope in a fraction of the time, helping businesses meet growing market demands.

Reduced Waste

Precision engineering in ring twister machines minimizes fiber wastage. Controlled tension and uniform twisting reduce breakage, saving raw materials and lowering production costs.

Enhanced Product Quality

Consistent twist tension ensures that every rope produced has uniform strength, flexibility, and durability. Using a ring twister improves the final product quality, making ropes suitable for industrial, commercial, and consumer applications.

Versatility in Rope Production

These machines handle a variety of fibers, including cotton, jute, nylon, and polypropylene, making them versatile tools for rope manufacturers looking to diversify their product line.

Scalability for Large Operations

With adjustable speeds and capacities, ring twister machines can scale production to meet increasing demands. Manufacturers can expand operations without needing additional labor or equipment.

Industrial Applications of Ring Twister Machines

- Rope Manufacturing: The primary application of ring twister machines is in the production of ropes of various sizes and strengths. These machines are used in industries ranging from shipping and construction to agriculture and textiles.

- Cord and Thread Production: Manufacturing of cords, threads, and multi-strand lines for packaging, textiles, and industrial bindings.

- Export and Wholesale Applications: High-quality ropes produced by ring twister machines meet international standards, making them suitable for global export markets. Manufacturers benefit from increased revenue and market reach.

- Specialized Industrial Uses: Industries requiring high-strength, customized ropes—such as marine, mining, and safety equipment—rely on ring twister machines to produce consistent, reliable products.

Ring Twister Machine Features

- Adjustable Speed Control: Allows operators to modify twist rates for different rope sizes.

- Durable Components: High-grade steel and precision engineering extend machine lifespan.

- Low Maintenance: Designed for easy operation with minimal maintenance requirements.

- Energy Efficient: Reduces operational costs while maintaining high output.

- Safety Features: Protective covers, emergency stops, and automated tension controls enhance workplace safety.

Why Choose Us

At Aawadkrupa Plastomech Pvt. Ltd., we specialize in manufacturing high-quality ring twister machines that combine efficiency, durability, and precision. Our expertise ensures that every machine meets international standards, providing reliable performance and consistent output. By choosing us, customers gain access to innovative solutions that save time, reduce waste, and elevate the quality of rope production. Our dedication to customer satisfaction, technical support, and product excellence makes us a preferred ring twister machine manufacturer and exporter in India and beyond.

Conclusion

A ring twister machine is an indispensable asset for modern rope manufacturing, offering unparalleled efficiency, reduced material waste, and superior product quality. With advanced features, versatile applications, and high durability, these machines empower manufacturers to scale operations, diversify products, and meet industry standards. Investing in a ring twister machine from Aawadkrupa Plastomech Pvt. Ltd. ensures reliable performance, consistent output, and long-term benefits for businesses. From producing industrial ropes to specialized cords and threads, our machines cater to a wide range of industrial and export requirements, making them a vital tool for growth and success.

For more information about Ring Twister Machine call us at +91 9510186014 or email info@akiropes.com.