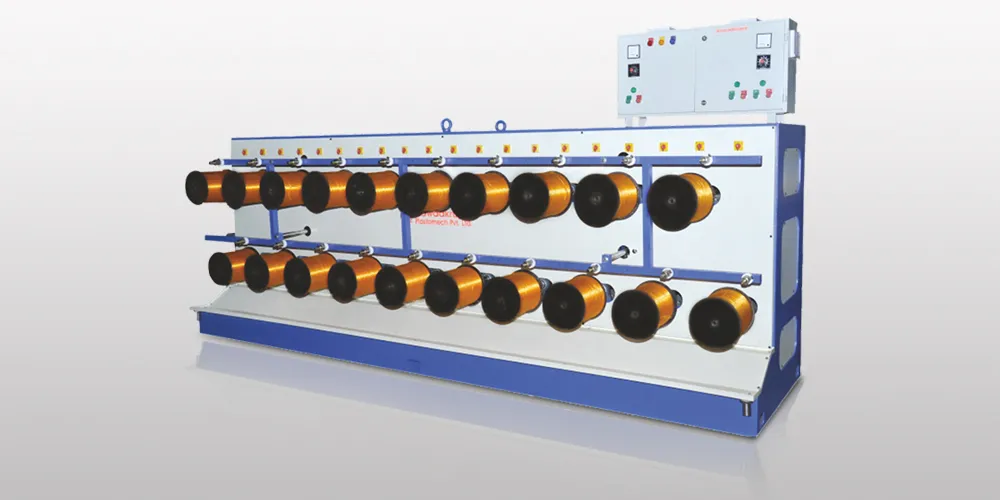

Aawadkrupa Plastomech Pvt. Ltd. is a leading Manufacturer of Fishing Line Winder, specializing in manufacturing and exporting advanced Fishing Line Winder Machines that meet the evolving needs of global textile and rope manufacturers. In the textile and rope manufacturing industry, achieving precision in yarn and thread winding is critical to maintaining product quality, operational efficiency, and reducing material waste. Among the most crucial machines used for this task is the Fishing Line Winder Machine. Designed specifically for high-precision applications, this machine plays a vital role in handling delicate yarns, synthetic fibers, and fishing lines with remarkable control and accuracy. With years of expertise in engineering excellence, our machines are trusted worldwide for their durability, speed, and accuracy in winding. Whether you’re a small-scale production unit or a high-volume operation, our machines are built to streamline your winding operations while maintaining the highest quality standards.

What is a Fishing Line Winder Machine?

A Fishing Line Winder Machine is a specialized piece of equipment used to wind fishing line or fine yarn onto bobbins, cones, or spools in a uniform and precise manner. Unlike basic winding systems, these machines are designed for high-tension, fine-gauge materials that require careful handling. Fishing lines, monofilament yarns, braided cords, and other lightweight fibers can be wound without stretching or damaging the material. This winding process begins by feeding the yarn from a supply spool or creel. The material passes through tension controls and guiding rollers before being wound tightly and uniformly onto the target bobbin or spool. The accuracy of winding helps prevent snarls, tangles, and inconsistencies during downstream processes like weaving, braiding, or fishing line deployment.

Key Features of Advanced Fishing Line Winders

Modern Fishing Line Winder Machines from Aawadkrupa Plastomech Pvt. Ltd. are designed with precision engineering and operator ease in mind. Here are some of the standout features:

- Variable Speed Controls: Allows for customization based on yarn thickness and material type

- Precision Traverse Mechanism: Ensures even layering and tight, consistent winding

- Digital Tension Settings: Helps avoid overstretching or under-winding

- Automatic Stop System: Halts the machine upon bobbin completion or yarn break

- Compatibility: Works with various yarns, including monofilaments, braided fishing lines, and fine textiles

Each feature is optimized to increase production efficiency while maintaining tight control over winding quality.

How Does a Fishing Line Winder Machine Work?

The working process of a Fishing Line Winder Machine involves a series of well-coordinated mechanical movements that contribute to consistent and controlled winding. Here’s a breakdown:

- Yarn Feed: The machine pulls yarn or line from a supply package

- Tension Regulation: Tension devices maintain steady pressure to avoid slack or overstretching

- Traverse Mechanism: Guides the yarn back and forth over the rotating bobbin, forming even layers

- Winding Section: The yarn is wrapped precisely onto the bobbin, cone, or spool

- Cut-Off & Reset: Automatic systems stop winding at preset lengths or diameters, allowing for easy resets

Our Fishing Line Winder Machines Manufacturer designs this system to minimize vibration and noise, offering stable performance even under continuous operation.

Importance in Rope and Fishing Line Manufacturing

The quality of winding has a direct impact on how effectively the rope or fishing line performs during end use. Misaligned layers or inconsistent winding can result in tangling, knotting, or premature wear. Precision winding with a Fishing Line Winder Machine helps manufacturers:

- Increase operational speed

- Reduce production downtime

- Minimize material waste

- Improve product strength and reliability

- Achieve uniform packaging and product presentation

From lightweight synthetic fishing lines to heavy-duty industrial threads, the ability to maintain consistent tension and precise layering is crucial in today’s competitive manufacturing landscape.

What Makes Our Machines Stand Out

As a trusted Fishing Line Winder Machine Manufacturer, Aawadkrupa Plastomech Pvt. Ltd. brings several advantages to the table:

- Customization Options: Machines can be tailored to specific bobbin sizes, yarn types, and output speeds

- User-Friendly Interface: Simple touchscreens and dial settings for easy adjustments

- Sturdy Build Quality: Built to withstand heavy use in industrial settings

- After-Sales Support: Comprehensive service network for training, installation, and technical assistance

- Global Reach: Successfully supplying to over 60 countries worldwide

These unique selling points make our machines a preferred choice for clients who prioritize both performance and reliability.

Applications Across Industries

The use of Fishing Line Winder Machines spans a wide array of industries:

- Fishing Gear Production: Monofilament and braided line winding

- Rope & Cord Manufacturing: Uniform winding of twisted or braided yarns

- Sports Equipment: Fishing reels, tennis strings, kite lines

- Technical Textiles: Winding fine industrial filaments used in reinforcement fabrics or insulation

- Automotive & Aerospace: Precise packaging of technical yarns and carbon fibers

The machine’s versatility allows it to adapt to different requirements without sacrificing performance or accuracy.

Benefits of Investing in a Quality Winder

- Better Output Consistency

Every bobbin produced meets quality standards - Improved Efficiency

Faster winding cycles save time and boost throughput - Reduced Material Waste

Accurate control over tension and alignment - Enhanced Worker Safety

Advanced designs include protective shields and safety sensors - Long-Term Cost Savings

Minimal maintenance and energy-efficient motors reduce operational expenses

Our customers often report immediate improvements in workflow and product uniformity after switching to our machinery.

Why Choose Us

At Aawadkrupa Plastomech Pvt. Ltd., we don’t just sell machines; we deliver complete winding solutions tailored to your production goals. With decades of experience in the textile machinery sector, our focus lies in offering high-precision, durable, and technology-driven machines that support modern manufacturing demands. As a leading Fishing Line Winder Machine Manufacturer, we work closely with our clients to develop custom solutions that are both scalable and cost-effective. From installation to after-sales service, our dedicated support team ensures smooth integration and long-term performance. Trust us to be your partner in achieving superior winding quality and production efficiency.

Conclusion

The Fishing Line Winder Machine is a cornerstone of modern textile and rope manufacturing. It provides the precision, consistency, and control needed to produce high-quality, tangle-free fishing lines and technical yarns. As production requirements grow more demanding, investing in a reliable, versatile, and high-speed winding solution becomes essential. Aawadkrupa Plastomech Pvt. Ltd. continues to lead the industry by offering machines that combine mechanical strength with digital intelligence, serving clients across diverse sectors with unmatched reliability.

Want to improve precision and speed in your production line with a Fishing Line Winder Machine? Call us at +91 9510186014 or email us at info@akiropes.com today.