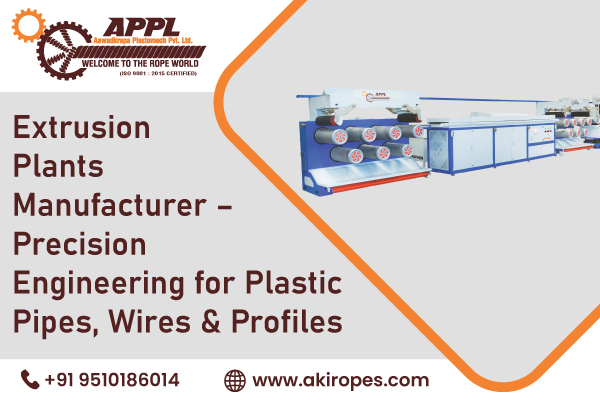

In today’s fast-growing industrial world, manufacturing precision and material optimization define success in plastics production. The extrusion process has become the backbone of modern plastic fabrication — from pipes and wires to intricate profiles used in construction, electrical, and automotive applications. Aawadkrupa Plastomech Pvt. Ltd. stands at the forefront as a trusted extrusion plant manufacturer, delivering advanced machinery engineered for consistency, power efficiency, and long-term reliability.

The demand for high-performance extrusion plants has increased dramatically due to the need for superior quality, smooth surface finish, and dimensional accuracy. These plants have become indispensable for manufacturers seeking faster output and minimal wastage. This detailed blog explores the features, applications, advantages, and pricing factors of an extrusion plant, helping industries make informed investment decisions that align with production goals and market requirements.

Understanding the Role of Extrusion Plants in Modern Manufacturing

An extrusion plant is an industrial setup that shapes raw plastic materials into continuous profiles by melting, forming, and cooling polymers under precise temperature and pressure control. The process delivers an uninterrupted stream of plastic pipes, wires, sheets, or custom shapes that can be cut or rolled for distribution.

From household plumbing to fiber optic cables, extrusion systems enable precision control over wall thickness, tensile strength, and flexibility. Advanced models are now digitally controlled, allowing manufacturers to optimize production speed, material flow, and output quality. When sourced from a reliable extrusion plant manufacturer, these systems offer years of dependable service with minimal maintenance requirements.

How an Extrusion Plant Works – Step-by-Step

A high-quality plastic extrusion plant integrates several coordinated stages to maintain steady performance and material integrity throughout production.

- Material Feeding – Plastic granules or compounds are fed into a hopper.

- Melting Zone – A heated barrel with rotating screws melts the material into a uniform molten state.

- Extrusion Process – The molten polymer passes through a die, forming a continuous profile of the desired shape.

- Cooling and Calibration – The extruded material is cooled, shaped, and stabilized using vacuum and water baths.

- Haul-off and Cutting – The product is pulled by a take-up unit and cut into desired lengths or rolled for packaging.

This seamless process produces consistent output across multiple shifts, allowing industries to scale production without compromising product quality.

Advantages of a High-Performance Extrusion Plant

Investing in a modern extrusion plant delivers measurable benefits for manufacturers operating across various industries.

- Precision and Consistency: A well-engineered extrusion plant manufacturer designs machines that maintain precise dimensional tolerances and flawless finishes — key for applications like pipes and wire coatings.

- Energy Efficiency: The latest models operate at lower power consumption while maintaining high throughput, optimizing long-term operational costs.

- High-Speed Output: Modern systems deliver faster production cycles, enabling industries to meet growing market demands efficiently.

- Material Versatility: A robust plastic extrusion plant can process a variety of materials — including PVC, HDPE, LDPE, PP, and nylon — offering flexibility to manufacturers.

- Durability and Longevity: Machines from an experienced extrusion plant manufacturer in india are designed for continuous operation under high load conditions, offering years of reliable performance.

Extrusion Plant Applications – Across Diverse Industries

The scope of an extrusion plant extends far beyond plastic pipe production. These systems are widely used across multiple industrial segments:

- Construction: Manufacturing water and drainage pipes, electrical conduits, and window profiles.

- Electrical: Producing wire coatings, insulation layers, and cable sheathing.

- Automotive: Creating flexible tubes, seals, and decorative trims.

- Agriculture: Manufacturing drip irrigation pipes and protective tubing.

- Consumer Goods: Producing packaging materials, profiles, and flexible films.

The versatility of extrusion technology continues to drive innovation and productivity in every sector it serves.

Evaluating the Right Extrusion Plant Manufacturer

Choosing the right extrusion plant manufacturer requires balancing performance specifications, build quality, and after-sales support. Aawadkrupa Plastomech Pvt. Ltd. has mastered this balance by integrating advanced engineering design, precision machining, and digital automation.

When comparing suppliers, buyers should focus on:

- Output speed per production hour

- Material compatibility and changeover flexibility

- Die design and calibration system

- Power rating and efficiency levels

- After-sales technical service and spare part availability

These criteria directly influence both the extrusion plant price and long-term operational success.

Key Factors Affecting Extrusion Plant Price

The extrusion plant price varies depending on several elements such as:

- Machine Size and Output Capacity – Larger machines with higher throughput generally have a higher investment cost.

- Automation Level – PLC-controlled systems or touchscreen interfaces increase the cost but improve operational control.

- Material Type – Machines configured for multi-material operations add to initial pricing.

- Customization and Accessories – Add-ons like automatic feeders, digital control panels, and cooling tanks affect pricing.

While it may be tempting to choose the lowest-cost model, the real value of an extrusion plant for sale lies in its reliability, output stability, and service life.

Why Choose Us

Aawadkrupa Plastomech Pvt. Ltd. stands as a symbol of innovation, reliability, and engineering excellence in extrusion technology. With decades of industrial experience, we specialize in delivering high-performance extrusion plants built to meet diverse industrial needs. Our focus lies in precision design, robust construction, and user-friendly operation that allows consistent, uninterrupted production.

We work closely with clients to tailor configurations that fit their exact requirements — from pipe extrusion to wire and profile manufacturing. Our customer-first approach, backed by a skilled technical team and global reach, makes us one of the most trusted names among extrusion plant manufacturer networks worldwide.

Conclusion

The future of industrial manufacturing depends on reliable, efficient, and adaptable machinery. Investing in a precision-engineered extrusion plant helps manufacturers achieve consistent quality, reduced waste, and higher profitability. From pipe and wire production to specialized profiles, advanced systems designed by expert extrusion plant manufacturer in india partners like Aawadkrupa Plastomech Pvt. Ltd. deliver measurable value. By evaluating core features, energy efficiency, and after-sales support, industries can select a system that delivers long-term performance and growth. Precision engineering, automation, and durability define the true standard of excellence in today’s extrusion technology.

For more details on high-performance, precision-engineered extrusion solutions, call +919510186014 or email info@akiropes.com today — your trusted partner in advanced extrusion manufacturing.

FAQs

What factors affect extrusion plant price?

The extrusion plant price depends on output capacity, automation level, material compatibility, and die design. Energy efficiency and build quality also influence total investment.

How does a plastic extrusion plant differ from standard systems?

A plastic extrusion plant is specifically designed for processing polymers like PVC, HDPE, and PP into continuous shapes. It offers higher temperature control and screw precision for smoother finishes.

Can extrusion plants be customized for specific applications?

Yes, a reputed extrusion plant manufacturer offers custom configurations for unique pipe sizes, profile shapes, and production capacities.

Is Aawadkrupa Plastomech an extrusion plant exporter?

Yes, Aawadkrupa Plastomech Pvt. Ltd. is a global extrusion plant exporter, providing export-ready systems backed by technical documentation and after-sales support.

Are extrusion plants manufactured in India globally competitive?

Absolutely. Each extrusion plant manufacturer in india now integrates global standards with advanced engineering, offering top-quality systems at competitive pricing.