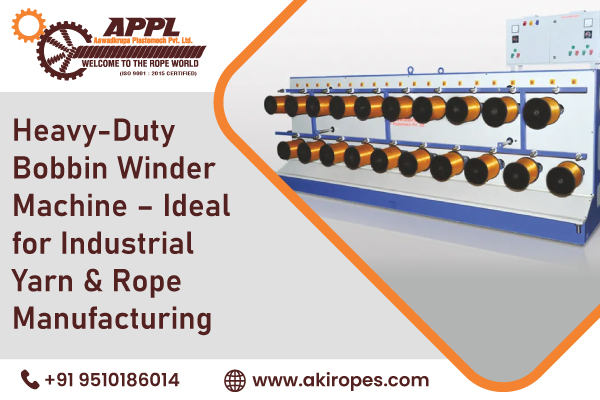

In modern industrial yarn and rope manufacturing, productivity, consistency, and precision define success. One machine that directly influences all three is the bobbin winder. From packaging strength to downstream processing efficiency, the quality of winding affects the entire production chain. A Heavy-Duty Bobbin Winder Machine is not just a supporting unit; it is a core production asset that determines operational stability and product uniformity. Aawadkrupa Plastomech Pvt. Ltd. designs and supplies industrial-grade bobbin winding solutions built for continuous operation, dimensional accuracy, and high-speed performance.

As industries expand their manufacturing capabilities and target higher output with reduced downtime, the demand for technically sound bobbin winding solutions continues to rise. Manufacturers today seek machines that handle different yarn types, maintain uniform tension, and operate reliably under heavy production loads. This detailed, title-oriented blog explains the importance, applications, performance characteristics, buying factors, and long-term value of a Heavy-Duty Bobbin Winder Machine while keeping the focus strictly on industrial yarn and rope production.

Understanding the Role of a Bobbin Winder Machine in Industrial Manufacturing

A bobbin winder machine is designed to wind yarn, thread, twine, or rope onto bobbins or spools in a controlled and uniform manner. This stage is crucial because uneven winding leads to inconsistent downstream processing, frequent yarn breaks, and reduced product quality. In industrial rope and yarn manufacturing, winding stability plays a direct role in tensile strength, tension control, and packaging reliability.

Heavy-duty winding machines are engineered to handle high tensile loads, varied yarn thicknesses, and extended operating cycles without vibration or mechanical fatigue. A high-performance bobbin winder supports smoother unwinding during weaving, twisting, or rope forming operations, improving line efficiency across the production unit.

Core Functional Principle of a Heavy-Duty Bobbin Winder Machine

A Heavy-Duty Bobbin Winder Machine operates by guiding the yarn from a supply package through tension regulators and guide systems before winding it evenly onto a rotating bobbin. The system maintains consistent tension through mechanical or electronic control units and distributes yarn uniformly across the bobbin surface using precision traverse mechanisms.

The quality of winding depends on synchronized motion between spindle speed, traverse length, and tension regulation. Industrial-grade machines maintain stable operation even at high speed, making them suitable for bulk production in rope, textile, and technical yarn units.

Importance of Heavy-Duty Construction in Bobbin Winder Machines

The durability of the machine structure defines its lifecycle value. Heavy-duty frames, precision-balanced spindles, hardened shafts, and industrial-grade bearings contribute to long operational life. In continuous manufacturing environments, lightweight machines often fail under sustained mechanical load, leading to frequent breakdowns and production losses.

A structurally reinforced Heavy-Duty Bobbin Winder Machine is designed to withstand vibration, temperature variation, and constant torque stress. This structural reliability supports higher uptime and lower maintenance frequency, which directly affects overall production cost control.

Productivity and Output Benefits in Yarn and Rope Manufacturing

Industrial yarn and rope systems demand uninterrupted flow of material across all process stages. The bobbin winder supports material handling efficiency by supplying evenly wound packages that unwind smoothly during twisting, braiding, extrusion, or weaving.

High-speed winding capability increases output per shift and aligns with automated twisting or rope-making operations. When integrated correctly, a Heavy-Duty Bobbin Winder Machine allows manufacturers to scale production without affecting consistency. This productivity advantage becomes critical when fulfilling large-volume industrial supply contracts.

Engineering Precision and Consistent Product Quality

Product consistency is a non-negotiable requirement in industrial yarn and rope markets. Poor winding leads to uneven tension, tangling, and non-uniform package density, creating defects later in production. A precision-engineered bobbin winder maintains controlled tension across the entire length of yarn being wound.

Aawadkrupa Plastomech Pvt. Ltd. develops winding machines with carefully calibrated mechanical components that support consistent layer formation and tension stability. This technical control supports predictable performance in downstream operations and improves final product reliability for end users.

Adaptability Across Industrial Applications

A Heavy-Duty Bobbin Winder Machine is used across a range of industries including rope manufacturing, packaging yarn processing, textile yarn preparation, fishing net production, and industrial cord fabrication. The adaptability of the machine across different yarn types and thickness ranges improves overall plant utilization.

Manufacturers benefit from reduced dependency on specialized winding equipment for each product category. A single robust system supports multiple production requirements through adjustable speed control and tension settings.

Performance Stability in Continuous Production Environments

Industrial units commonly operate in multi-shift cycles where machines run for long hours without interruption. Performance stability under such conditions is critical. Heavy-duty winding machines are built to deliver steady output under continuous rotational load without developing mechanical slack or spindle imbalance.

Stable winding ensures that production planning remains predictable and helps maintain consistent delivery schedules. Machine reliability here directly influences inventory management and order fulfillment performance.

Market Demand and Industrial Value of Bobbin Winder Machines

The growing demand for industrial ropes, cords, and technical yarns has increased the relevance of advanced winding systems. Global manufacturers now prioritize machine efficiency, operational safety, and precision output over initial purchase savings.

A well-designed Heavy-Duty Bobbin Winder Machine supports long-term production economics by reducing labor dependence, minimizing waste, and supporting smoother integration with automated production lines. These factors make bobbin winding technology a critical investment for expanding manufacturing units.

Technical Design Focus and System Integration

Modern bobbin winder systems focus on vibration control, speed stability, adjustable traverse mechanisms, and centralized control panels. Integration with upstream and downstream machines allows synchronized operation across the entire production line.

The technical design approach followed by Aawadkrupa Plastomech Pvt. Ltd. focuses on robust mechanical construction paired with accurate motion control. This combination supports wide material compatibility and predictable production behavior under different load conditions.

Industrial Packaging and Handling Advantages

Finished bobbins produced on a Heavy-Duty Bobbin Winder Machine have uniform shape, density, and alignment. These factors improve stacking, transportation, and storage stability. Uniform packaging directly improves supply chain handling efficiency and reduces damage during transit.

For export-oriented manufacturers, properly wound bobbins contribute to better inspection outcomes and improved acceptance across international markets.

Standardization and Customization Flexibility

Industrial manufacturing often requires machine configurations that align with specific plant layouts and product specifications. Heavy-duty bobbin winder machines can be developed in varying spindle counts, winding speeds, and tension ranges.

Aawadkrupa Plastomech Pvt. Ltd. supports both standardized production models and customized configurations based on client application requirements. This flexibility allows manufacturers to align capital investment with real production demands.

Why Choose Us

Aawadkrupa Plastomech Pvt. Ltd. is dedicated to delivering industrial-grade winding solutions that support consistent production performance and long-term reliability. Our engineering team focuses on structural strength, precise mechanical alignment, and smooth operational behavior across every Heavy-Duty Bobbin Winder Machine supplied.

With deep understanding of industrial yarn and rope processing requirements, we align machine performance with real production demands rather than theoretical capacity. Aawadkrupa Plastomech Pvt. Ltd. continues to build trusted partnerships by supplying machines that support stable output, low downtime, and predictable maintenance. Our commitment to quality fabrication, technical clarity, and after-sales responsiveness positions us as a dependable manufacturing partner for growing industrial operations.

Conclusion

A Heavy-Duty Bobbin Winder Machine plays a central role in supporting consistent yarn handling and stable rope manufacturing output. Its structural strength, precision winding capability, and operational reliability directly influence product quality and production efficiency. Manufacturers investing in heavy-duty winding systems gain long-term advantages in workflow stability, packaging uniformity, and downstream processing performance.

As industrial yarn and rope sectors continue to expand, the demand for robust winding solutions will grow alongside automation and productivity targets. Selecting the right machine partner allows manufacturers to strengthen output consistency, reduce operational interruptions, and achieve sustainable production performance across competitive markets.

For more information on a Heavy-Duty Bobbin Winder Machine ideal for industrial yarn and rope manufacturing, call +91 9510186014 or email info@akiropes.com today for expert technical guidance.

FAQs

What is the main function of a Heavy-Duty Bobbin Winder Machine?

The primary function is to wind yarn, rope, or thread onto bobbins in a uniform and controlled manner for smooth downstream processing and stable packaging.

Which industries commonly use bobbin winder machines?

These machines are widely used in yarn manufacturing, rope production, textile processing, fishing net fabrication, and industrial cord manufacturing units.

What defines a heavy-duty bobbin winder?

It is defined by robust structural construction, precision spindle balance, stable tension control, and the ability to operate continuously under high load conditions.

Does machine quality affect downstream production?

Yes, winding consistency directly influences unwinding behavior, tension stability, and final product uniformity in twisting, weaving, and rope-making processes.

Can a bobbin winder machine be customized for different applications?

Yes, industrial models can be configured for different yarn thicknesses, bobbin sizes, speed ranges, and production layouts based on plant requirements.